In 2025, the KBS Sugar Mill in Thailand

encountered a serious challenge in transferring A massecuite.

The existing transfer pump failed and could no longer operate reliably before the start of the crushing season.

A massecuite with a Brix of 90°–95° has an extremely high viscosity of up to

100,000 cP, and it also contains solid sugar crystals.

These characteristics caused frequent existing pump failures, high maintenance costs, and unstable production.

KBS Sugar Mill urgently needed a reliable

replacement pump that could handle high viscosity, crystal-containing sugar

paste and be installed before the production season.

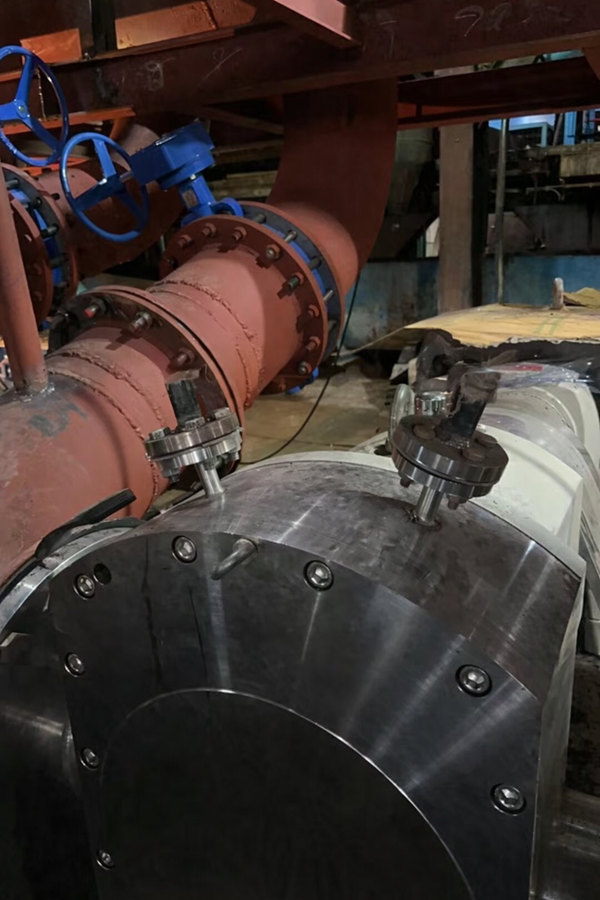

Solution: Bonve Lobe Pump for A Massecuite Transfer

With extensive experience in sugar industry applications, Bonve Lobe Pump was selected to provide a customized solution for KBS Sugar Mill.

Based on the operating conditions of 90°–95° Brix A massecuite, and the required flow rate of 50 m³/h and discharge pressure of 15 bar,

We recommended the following solution:

Pump Model: 300BV12-200

Motor Power: 55 kW

Output Speed: 65–68

rpm

Drive: Large-size gear reducer for high

torque output

The low rotational speed combined with high

torque enables the pump to overcome high pipeline resistance during

long-distance transfer, while effectively protecting sugar crystals from

damage.

Why Bonve Lobe Pumps Are Ideal for A

Massecuite

Rotary lobe pumps offer several key

advantages in high Brix sugar paste applications:

1. Excellent Performance with High

Viscosity Media

Rotary lobe pumps maintain stable flow even

when handling viscosities up to 100,000 cP, making them ideal for thick A

massecuite.

2. Gentle Handling of Sugar Crystals

The low shear, low speed design prevents

crystal breakage, ensuring consistent sugar quality and downstream process

stability.

3. High Torque at Low Speed

With a heavy-duty gearbox and low RPM

operation, the pump delivers strong torque, allowing smooth start-up and

continuous operation under high load conditions.

4. Stable Flow and Pressure

The pump provides pulsation-free and stable

output, which is critical for continuous sugar production processes.

5. High Reliability and Low Failure Rate

Designed for harsh industrial environments,

rotary lobe pumps significantly reduce downtime and maintenance frequency

compared to conventional pump types.

Installation & Operation Results

The rotary lobe pump was successfully

installed and commissioned in October 2025.

During the December production season, the pump operated continuously and stably transferred A massecuite for KBS Sugar Mill.

The operational performance has been highly

satisfactory, meeting all flow, pressure, and reliability requirements.

Technical Parameters

Medium: A Massecuite

Brix: 90°–95°

Viscosity: 100,000 cP

Temperature: 75°C

Pump Model: 300BV12-200

Flow Rate: 50 m³/h

Discharge Pressure: 15 bar

Output Speed: 65 rpm

Motor: 55 kW

For more details please contact me:

Andre Chen

Sales Engineer

Mobile/whatsapp/Wechat: +86 15888591452

Email: bvsales2@bonvepumps.com