Bonve Rotary Lobe Pump with Thermosiphon System

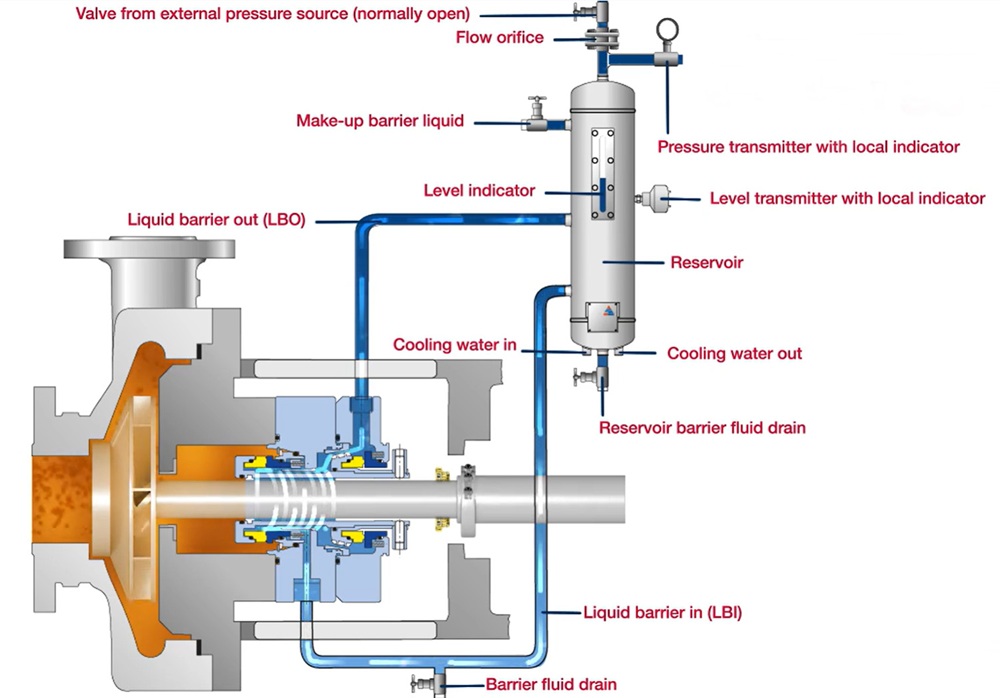

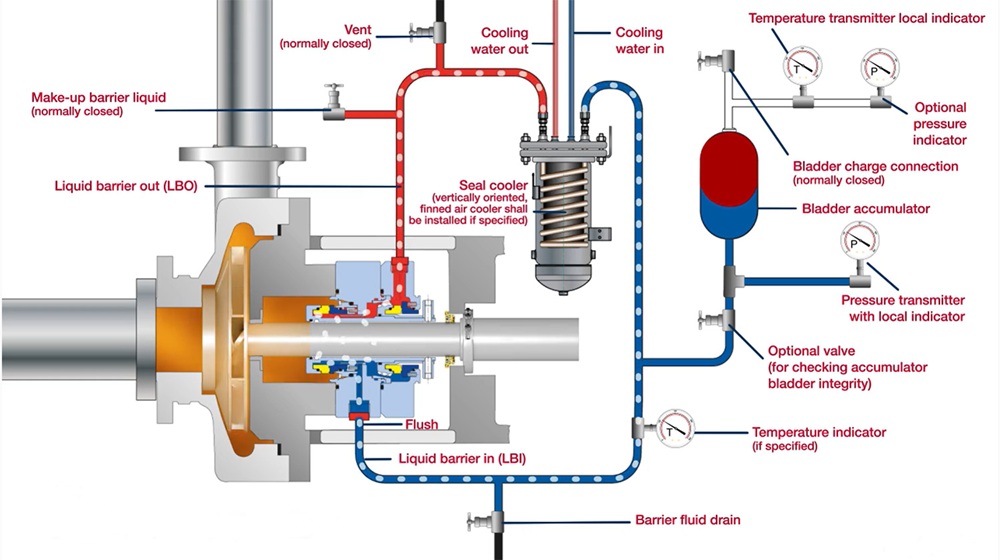

When oil company transfer toxic, flammable, explosive, or corrosive fluids, it must minimize the risk of on-site accidents caused by potential mechanical-seal failures. In accordance with API 676, rotary lobe pumps are therefore fitted with double mechanical seals and an API 682–compliant thermosiphon system (PLAN53A, PLAN53B, or PLAN54). A pressurized barrier fluid, maintained by the accumulator in the thermosiphon system, prevents medium from escaping to atmosphere. The barrier fluid cools and lubricates the seal faces; heat generated by the seal is removed in an external water- or air-cooled heat exchanger. This arrangement markedly improves the operating environment of the mechanical seal, enhances its reliability, extends its service life, and ensures continuous, efficient pump operation.

Instrumentation installed on the thermosiphon system—including pressure transmitters, temperature transmitters, pressure gauges, and thermometers—provides operators with real-time data for routine inspections. Should the double mechanical seal begin to fail, accumulator pressure will drop. Once the decreasing pressure reaches the low-alarm set point of the pressure transmitter, the transmitter sends an alarm signal to the DCS, enabling operators to shut down the pump promptly for inspection and maintenance.

API 682 -PLAN53A PID

API 682 -PLAN53B PID

External Pressure Safety Valve

Over-pressure protection. Prevents the pump and downstream piping from exceeding their design pressure if the discharge line becomes blocked or throttled.

Drip Pan Design

1.Keeps toxic, flammable, or corrosive liquids off the skid and walkways, reducing fire, explosion, and health risks and simplifying decontamination.

2.Allows controlled drainage of collected liquid to a closed drain or recovery vessel for safe disposal or recycle, maintaining a clean and compliant installation .

Sealing Reliability

1.Double mechanical seals (SiC/SiC or TC/TC) with FFKM elastomers ensure zero leakage under 1.2MPa pressure.

2.Patented shaft key synchronization prevents rotor collision during instant starts.

Material in contact with the medium

1.Stainless steel 304, 316, 316L

2.Duplex stainless steel 2205, 2507

Typical media transfer:

Light hydrocarbons, propylene glycol, methanol, ethanol, oxazolidinone, isopropyl ether, n-pentane, DBP solvent, benzene, toluene, xylene, acid/alkali-laden chemical wastewater, liquid chlorine, aniline, hydrogen sulfide solution, sulfur-containing effluent, concentrated sulfuric acid, concentrated nitric acid, hydrofluoric acid, sodium hydroxide solution, and many others.

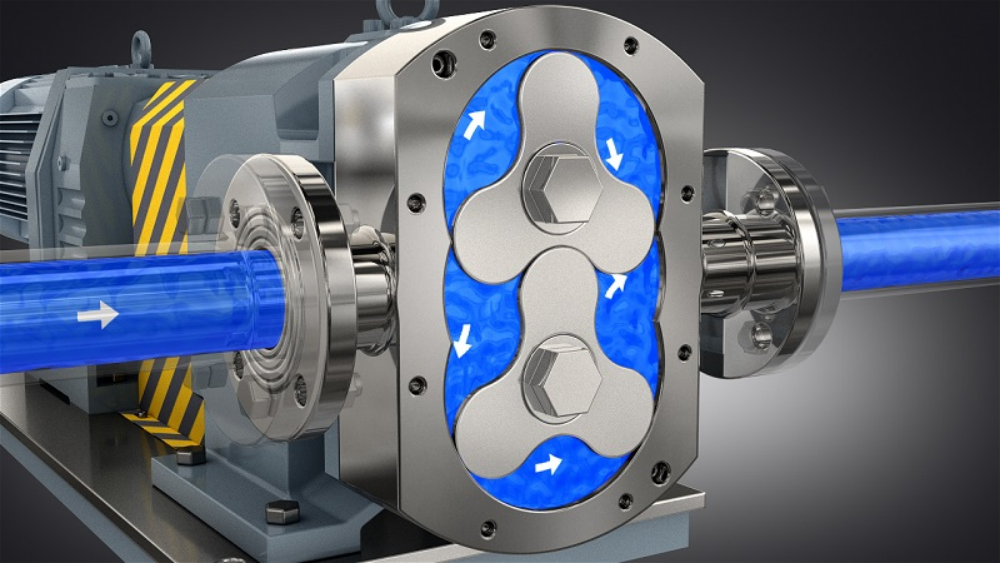

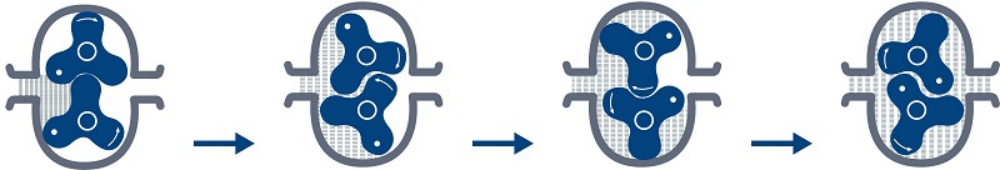

Bonve lobe pumps basically consist of two lobe rotors, which rotate synchronously driven by a pair of synchronous gears in the gearbox. The rotors are driven by the main shaft and sub-shaft to rotate in a synchronous reverse direction, which changes the pump capacity, builds up high vacuum and discharge pressure, thus an efficient pumping is formed. Gap is kept between the rotors and between the pump casing, no friction, long life, no damage, no physical and chemical reaction to the pumped products.

· Bi-wing rotor diagram

·

· Tri-lobe rotors diagram

·

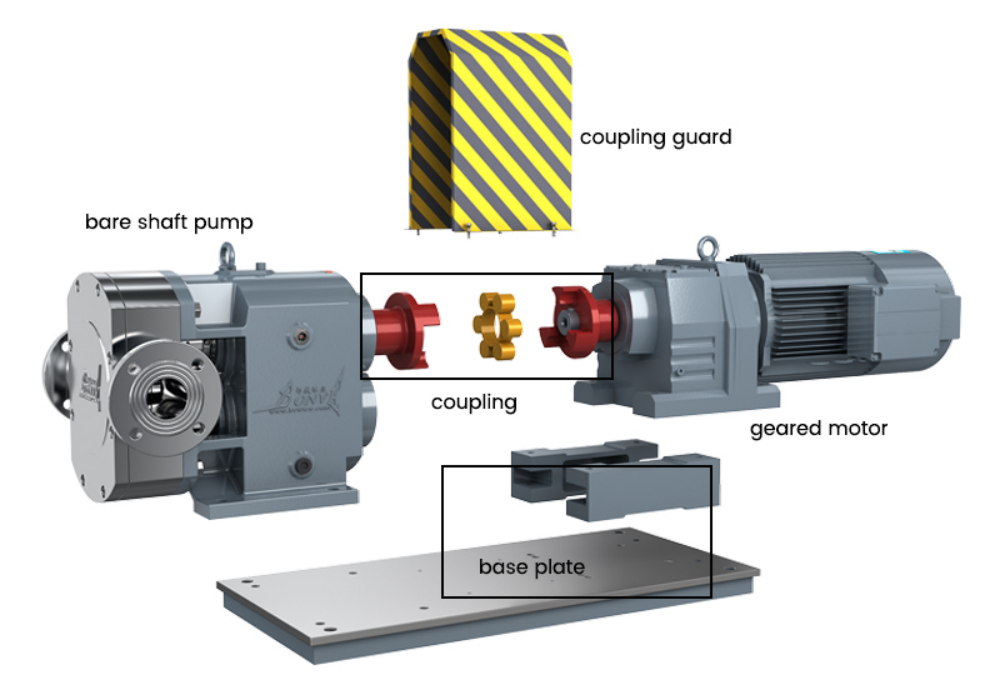

Main Parts of the Complete Pump

Bonve complete pumps are usually composed of bare shaft pump, coupling and its guard, geared motor and base plate. With your order, bare shaft pump or complete pump is supplied.

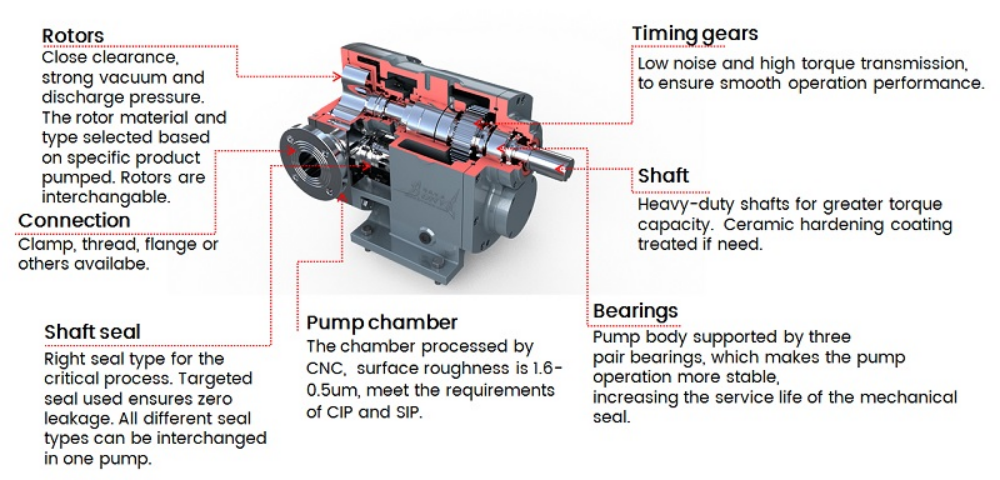

Bare Shaft Pump Structure

Structure Details

Bonve has an advantage over lobe pump that no other company can match.

1.Rotor:The error of the rotors processed by CNC is extremely small. The unique rotor perfectly seals the inlet and outlet of the pump. The vacuum degree of the pump is up to -0.095MPA. The rotor material and type can be selected according to the characteristics of the pumped product.

2.Shaft: The transmission shaft is processed by CNC machining center, which has characteristics of high precision, high bending strength and strong wear resistance.

3.Pump cavity: The pump cavity is sealed by a pump cover that can be opened quickly, enabling quick maintenance of the pump. The pump body is processed by CNC machining.

4.Gears:High-precision, High-Standard synchronous gears have good meshing, smooth transmission, low noise, and excellent bearing capacity.

5.Mechanical seal: The seal material and type are selected according to the characteristic of the pumped product, to ensure zero leakage, no pollution, and more environmental production.

6.Bearings: Six bearings arranged in a separate arrangement increase the concentricity of the pump operation, enhance the bearing capacity of the shaft and make the pump running more stable, thereby increasing the service life of the shaft and the mechanical seal.

7.Gear box: The gear box is processed by CNC, with high precision, high concentricity and strong versatility.

8.Spindle:We use splines the bearings and spindle, makes the pump less likely to slip. The high-precision spline makes the pump run more smoothly, and the service life is much higher than that of its peers.

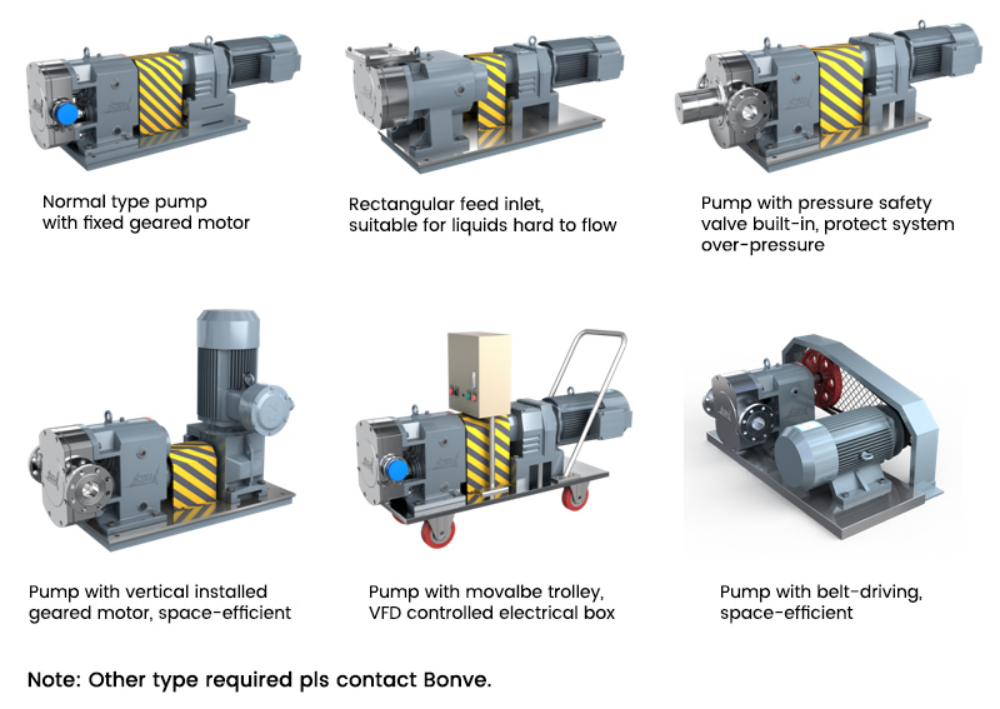

Complete Pump Types

Technical Parameters

|

Model |

Displace -ment |

RPM |

Flow |

Dis. Pre. |

Power |

Vacuum |

Port size |

Max viscosity |

|

|

(L/r) |

(r/min) |

(m³/h) |

(Mpa) |

(kW) |

(Mpa) |

(mm) |

(cp) |

|

25BV12-05 |

0.06 |

10-1000 |

0-0.5 |

0-1.2 |

0.37-1.1 |

-0.080 |

25 |

1,500,000 |

|

40BV12-2 |

0.15 |

10-1000 |

0-2 |

0-1.2 |

0.75-2.2 |

-0.080 |

40 |

1,500,000 |

|

50BV12-5 |

0.32 |

10-800 |

0-5 |

0-1.2 |

1.5-4 |

-0.085 |

50 |

1,500,000 |

|

65BV12-10 |

0.65 |

10-600 |

0-10 |

0-1.2 |

2.2-7.5 |

-0.085 |

65 |

1,500,000 |

|

80BV12-20 |

1.74 |

10-500 |

0-20 |

0-1.2 |

4-15 |

-0.095 |

80 |

1,500,000 |

|

90BV12-30 |

2.60 |

10-500 |

0-30 |

0-1.2 |

5.5-22 |

-0.095 |

100 |

1,500,000 |

|

100BV12-40 |

3.65 |

10-500 |

0-40 |

0-1.2 |

7.5-30 |

-0.095 |

100 |

1,500,000 |

|

125BV12-50 |

4.60 |

10-500 |

0-50 |

0-1.2 |

7.5-37 |

-0.095 |

125 |

1,500,000 |

|

140BV12-70 |

6.10 |

10-500 |

0-70 |

0-1.2 |

11-45 |

-0.095 |

150 |

1,500,000 |

|

150BV12-80 |

7.63 |

10-500 |

0-80 |

0-1.2 |

11-55 |

-0.095 |

150 |

1,500,000 |

|

200BV12-120 |

11.56 |

10-400 |

0-120 |

0-1.2 |

15-75 |

-0.095 |

200 |

1,500,000 |

|

250BV12-150 |

14.22 |

10-400 |

0-150 |

0-1.2 |

18.5-90 |

-0.095 |

250 |

1,500,000 |

|

300BV12-200 |

20.80 |

10-300 |

0-200 |

0-1.2 |

22-110 |

-0.095 |

300 |

1,500,000 |

|

350BV12-300 |

32.60 |

10-250 |

0-300 |

0-1.2 |

45-160 |

-0.095 |

350 |

1,500,000 |

|

400BV12-400 |

50.40 |

10-250 |

0-400 |

0-1.2 |

55-200 |

-0.095 |

400 |

1,500,000 |

Note:

1. Tested medium: water. Your liquid's density, viscosity and temperature are necessary to supply when choose the pump.

2. Speed, flow rate, electrical power and pressure will be varified according to different liquid properties.

3. Port size can be changed as needed.

Selection Guidelines

|

Your Industry |

|

||

|

About pump medium |

Name: |

||

|

Density (g/m³): |

|||

|

Viscosity (mPa.s): |

|||

|

Temperature (℃): |

|||

|

PH value: |

|||

|

Solid content (%): |

|||

|

Solid size (mm): |

|||

|

Suction side |

Pressure: Positive ( ) bar; Negtive ( ) bar |

How high (m): |

|

|

Suction pipe length (m): |

Diameter (mm): |

||

|

Bends (Pcs): |

T-piece (Pcs): |

Valves (Pcs): |

|

|

Discharge side |

Pressure (Mpa): |

||

|

Vertical delivery pipe length (m): Total delivery pipe length (m): |

Diameter (mm): |

||

|

Bends (Pcs): |

T-piece (Pcs): |

Valves (Pcs): |

|

|

Required flow rate (L/H) |

Operating flow: |

Max. flow: |

|

|

Pump material required |

SS304 ( ) SS316 ( ) SS316L ( ) Duplex stainless steel ( ) |

||

|

Motor required |

Phase: Single ( ) Three ( ) |

Voltage (V): |

Frequency (Hz): |

|

IP grade: |

Energy efficiency: |

Anti-explosive: |

|

|

Installation type |

Fixed ( ) |

Movable ( ) |

% |

Contact Us

Don't miss out on the opportunity to upgrade your PVC resin transfer process—contact us today to learn more or request a quote!

Contact person: Andre Chen

Tel: +86-574-87769810 Fax: +86-574-62962898

Mobile/Whatsapp/Wechat: +86 15888591452

Email: bvsales2@bonvepumps.com