Chemical Grade SS316 Rotary Lobe Pump For Shampoo soap liquid

In the Field of High-Viscosity Daily Chemical Product Handling, Hygiene and Gentle Processing Are Critical

Bonve's advanced Stainless Steel Rotary lobe Pump is meticulously engineered to address the challenges of transferring high-viscosity daily chemical products such as shampoos, liquid soaps, hand sanitizers, and body washes. These products, rich in surfactants, thickeners, silicones, and fragrances, demand precision in handling to preserve texture, stability, and sensory properties.

Unique Structural Advantages

The rotor design ensures low-shear, pulsation-free transfer, critical for shear-sensitive formulations.

Precision-engineered rotors operate in synchronized motion to maintain consistent flow rates (0.5–400 m³/hr) without compromising viscosity or emulsified structures. Key features include:

Hygienic construction: All wetted parts use FDA-compliant SS316L or coated surfaces, preventing contamination and ensuring compliance with cosmetic-grade standards.

Self-clearing geometry: The rotor cavity design minimizes product residue, ideal for frequent batch changes.

Adaptive clearance control: Automatically compensates for wear, maintaining efficiency even with abrasive additives like exfoliating particles or salt-based thickeners.

Problem-Solving Capabilities

Traditional gear pumps or diaphragm pumps often fail due to high shear, incomplete evacuation, or seal degradation. Bonve’s Rotary lobe Pump resolves these issues with:

Shear-sensitive handling: Gentle transfer preserves foaming agents, microcapsules, and emulsion stability.

Sanitary surface finish: Mirror-polished surfaces (Ra ≤ 0.8 μm) and CIP/SIP compatibility eliminate cross-contamination risks.

Seal integrity: Triple-lip seals with PTFE or EPDM materials resist chemical corrosion from alcohols, essential oils, and acidic/alkaline formulations.

Speed versatility: Variable frequency drives (0–500 RPM) optimize flow for viscosities ranging from 500 to 200,000 cP.

This innovation reduces energy consumption by 30% compared to progressive cavity pumps and cuts product waste by 45% through precise evacuation.

Cross-Industry Versatility

Bonve's pump excels in diverse daily chemical applications:

Shampoos & conditioners: Maintains silicone oil suspension without separation.

Liquid soaps & sanitizers: Handles shear-thinning gels and alcohol-based solutions.

Lotion & cream bases: Transfers non-Newtonian fluids with minimal pressure fluctuation.

Color cosmetics: Prevents pigment settling in high-density serums.

Key Specifications

Viscosity range: 1–2,000,000 cP

Temperature resistance: -20°C to 180°C (with optional cooling/heating jackets)

Port sizes: DN25–DN150 (customizable)

Certifications: EHEDG, 3-A, REACH compliant

Operational Efficiency

The pump's quick-disassembly design reduces cleaning time by 50%, while its leak-free operation ensures compliance with GMP and ISO 22716 guidelines.

Whether in small-batch artisanal production or large-scale filling lines, Bonve delivers reliability that safeguards product quality and operational continuity.

Engineered for purity. Trusted for performance.

Bonve Pumps – Your Partner in Cosmetic Fluid Excellence.

About Bonve Stainless Steel Lobe Pump

Bonve Lobe Pump is a specialized positive - displacement pump with its non-contact pump element design has the ability to cover a wide range of applications in industry. The hygienic design, anti-corrosive stainless steel construction and smooth pumping action have long established these pumps in the food, beverage, dairy and pharmaceutical industries.

Features include:

• Gentle transfer of delicate suspended solids.

• Bi-directional operation.

• Compact size with high performance and low energy input.

• Ability to pump shear sensitive media.

• Easy maintenance.

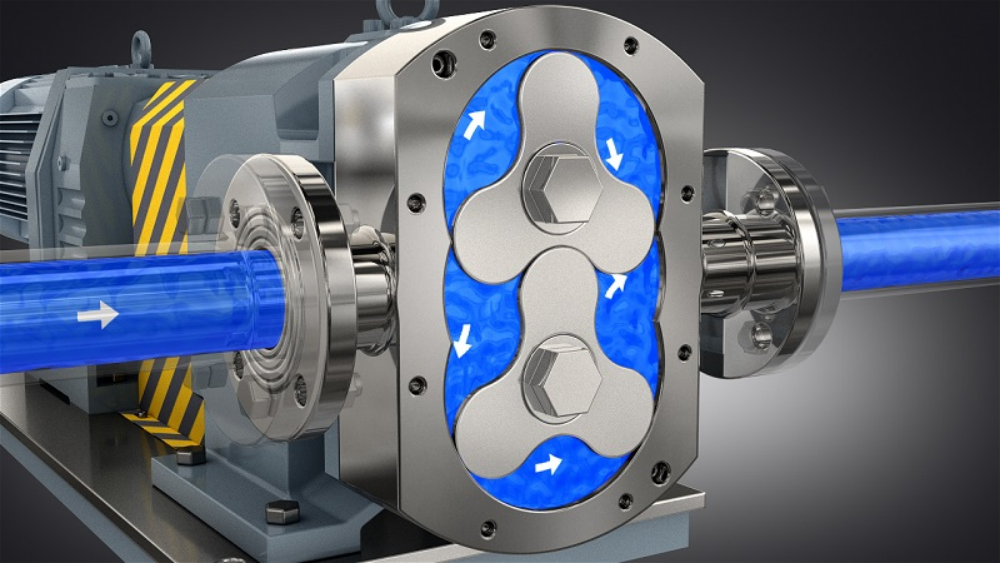

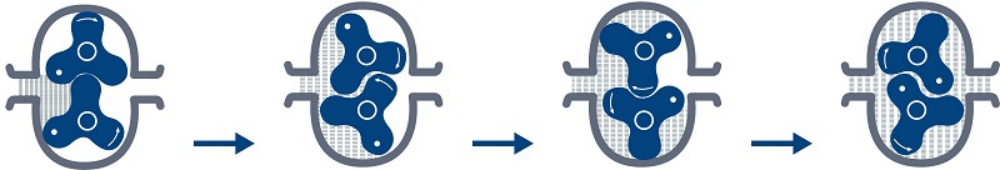

Bonve lobe pumps basically consist of two lobe rotors, which rotate synchronously driven by a pair of synchronous gears in the gearbox. The rotors are driven by the main shaft and sub-shaft to rotate in a synchronous reverse direction, which changes the pump capacity, builds up high vacuum and discharge pressure, thus an efficient pumping is formed. Gap is kept between the rotors and between the pump casing, no friction, long life, no damage, no physical and chemical reaction to the pumped products.

· Bi-wing rotor diagram

·

· Tri-lobe rotors diagram

·

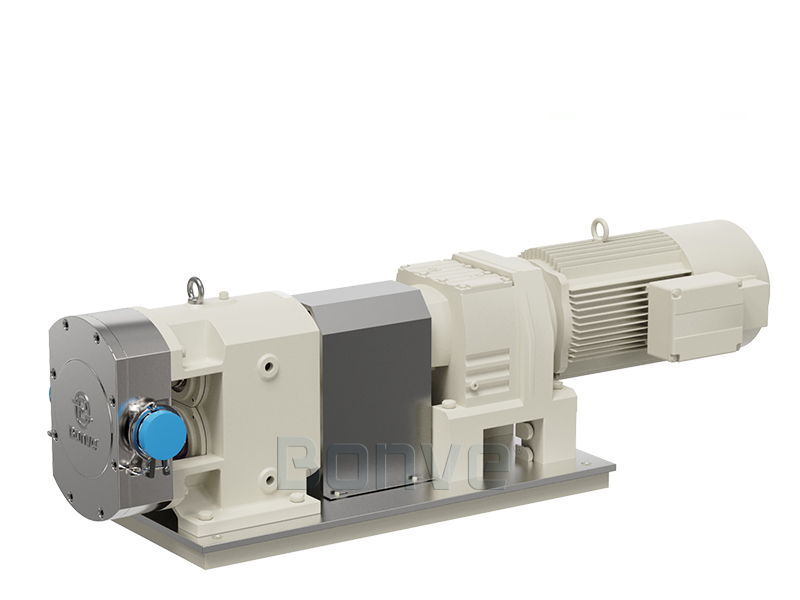

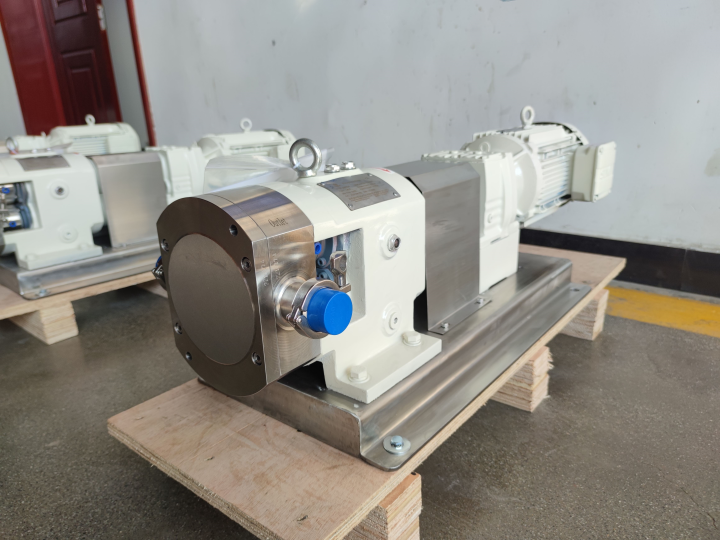

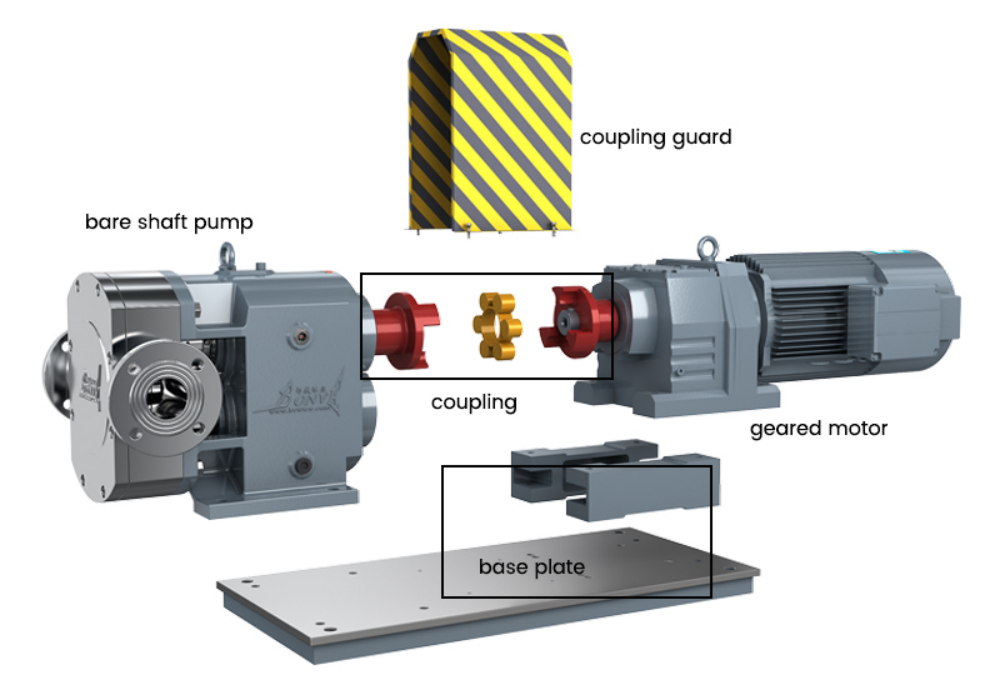

Main Parts of the Complete Pump

Bonve complete pumps are usually composed of bare shaft pump, coupling and its guard, geared motor and base plate. With your order, bare shaft pump or complete pump is supplied.

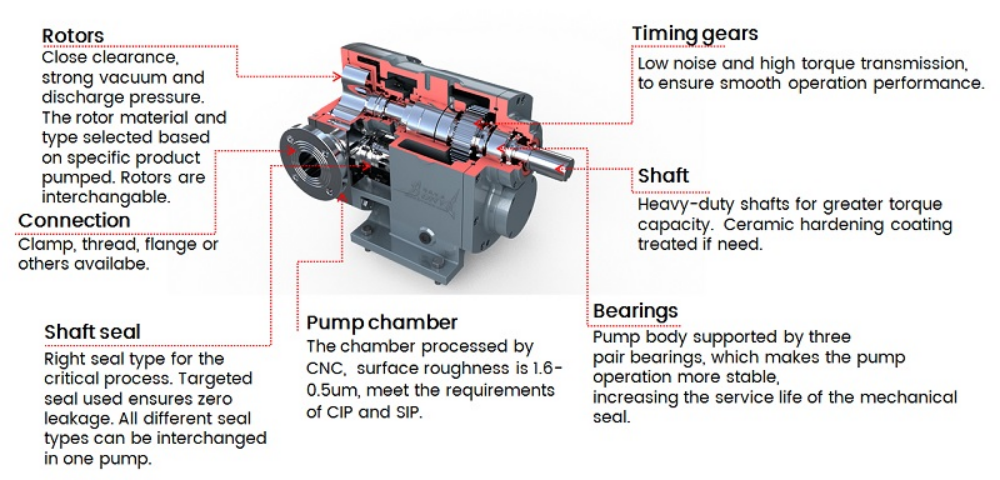

Bare Shaft Pump Structure

Structure Details

Bonve has an advantage over lobe pump that no other company can match.

1.Rotor:The error of the rotors processed by CNC is extremely small. The unique rotor perfectly seals the inlet and outlet of the pump. The vacuum degree of the pump is up to -0.095MPA. The rotor material and type can be selected according to the characteristics of the pumped product.

2.Shaft: The transmission shaft is processed by CNC machining center, which has characteristics of high precision, high bending strength and strong wear resistance.

3.Pump cavity: The pump cavity is sealed by a pump cover that can be opened quickly, enabling quick maintenance of the pump. The pump body is processed by CNC machining.

4.Gears:High-precision, High-Standard synchronous gears have good meshing, smooth transmission, low noise, and excellent bearing capacity.

5.Mechanical seal: The seal material and type are selected according to the characteristic of the pumped product, to ensure zero leakage, no pollution, and more environmental production.

6.Bearings: Six bearings arranged in a separate arrangement increase the concentricity of the pump operation, enhance the bearing capacity of the shaft and make the pump running more stable, thereby increasing the service life of the shaft and the mechanical seal.

7.Gear box: The gear box is processed by CNC, with high precision, high concentricity and strong versatility.

8.Spindle:We use splines the bearings and spindle, makes the pump less likely to slip. The high-precision spline makes the pump run more smoothly, and the service life is much higher than that of its peers.

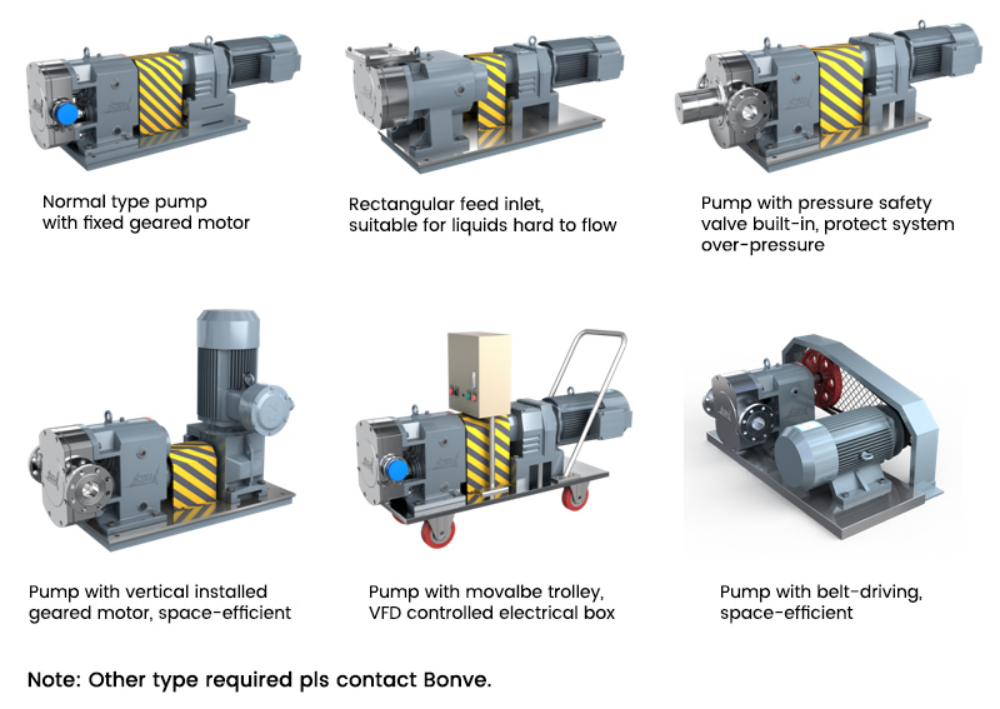

Complete Pump Types

Technical Parameters

|

Model |

Displace -ment |

RPM |

Flow |

Dis. Pre. |

Power |

Vacuum |

Port size |

Max viscosity |

|

|

(L/r) |

(r/min) |

(m³/h) |

(Mpa) |

(kW) |

(Mpa) |

(mm) |

(cp) |

|

25BV12-05 |

0.06 |

10-1000 |

0-0.5 |

0-1.2 |

0.37-1.1 |

-0.080 |

25 |

1,500,000 |

|

40BV12-2 |

0.15 |

10-1000 |

0-2 |

0-1.2 |

0.75-2.2 |

-0.080 |

40 |

1,500,000 |

|

50BV12-5 |

0.32 |

10-800 |

0-5 |

0-1.2 |

1.5-4 |

-0.085 |

50 |

1,500,000 |

|

65BV12-10 |

0.65 |

10-600 |

0-10 |

0-1.2 |

2.2-7.5 |

-0.085 |

65 |

1,500,000 |

|

80BV12-20 |

1.74 |

10-500 |

0-20 |

0-1.2 |

4-15 |

-0.095 |

80 |

1,500,000 |

|

90BV12-30 |

2.60 |

10-500 |

0-30 |

0-1.2 |

5.5-22 |

-0.095 |

100 |

1,500,000 |

|

100BV12-40 |

3.65 |

10-500 |

0-40 |

0-1.2 |

7.5-30 |

-0.095 |

100 |

1,500,000 |

|

125BV12-50 |

4.60 |

10-500 |

0-50 |

0-1.2 |

7.5-37 |

-0.095 |

125 |

1,500,000 |

|

140BV12-70 |

6.10 |

10-500 |

0-70 |

0-1.2 |

11-45 |

-0.095 |

150 |

1,500,000 |

|

150BV12-80 |

7.63 |

10-500 |

0-80 |

0-1.2 |

11-55 |

-0.095 |

150 |

1,500,000 |

|

200BV12-120 |

11.56 |

10-400 |

0-120 |

0-1.2 |

15-75 |

-0.095 |

200 |

1,500,000 |

|

250BV12-150 |

14.22 |

10-400 |

0-150 |

0-1.2 |

18.5-90 |

-0.095 |

250 |

1,500,000 |

|

300BV12-200 |

20.80 |

10-300 |

0-200 |

0-1.2 |

22-110 |

-0.095 |

300 |

1,500,000 |

|

350BV12-300 |

32.60 |

10-250 |

0-300 |

0-1.2 |

45-160 |

-0.095 |

350 |

1,500,000 |

|

400BV12-400 |

50.40 |

10-250 |

0-400 |

0-1.2 |

55-200 |

-0.095 |

400 |

1,500,000 |

Note:

1. Tested medium: water. Your liquid's density, viscosity and temperature are necessary to supply when choose the pump.

2. Speed, flow rate, electrical power and pressure will be varified according to different liquid properties.

3. Port size can be changed as needed.

Selection Guidelines

|

Your Industry |

|

||

|

About pump medium |

Name: |

||

|

Density (g/m³): |

|||

|

Viscosity (mPa.s): |

|||

|

Temperature (℃): |

|||

|

PH value: |

|||

|

Solid content (%): |

|||

|

Solid size (mm): |

|||

|

Suction side |

Pressure: Positive ( ) bar; Negtive ( ) bar |

How high (m): |

|

|

Suction pipe length (m): |

Diameter (mm): |

||

|

Bends (Pcs): |

T-piece (Pcs): |

Valves (Pcs): |

|

|

Discharge side |

Pressure (Mpa): |

||

|

Vertical delivery pipe length (m): Total delivery pipe length (m): |

Diameter (mm): |

||

|

Bends (Pcs): |

T-piece (Pcs): |

Valves (Pcs): |

|

|

Required flow rate (L/H) |

Operating flow: |

Max. flow: |

|

|

Pump material required |

SS304 ( ) SS316 ( ) SS316L ( ) Duplex stainless steel ( ) |

||

|

Motor required |

Phase: Single ( ) Three ( ) |

Voltage (V): |

Frequency (Hz): |

|

IP grade: |

Energy efficiency: |

Anti-explosive: |

|

|

Installation type |

Fixed ( ) |

Movable ( ) |

% |

Contact Us

We welcome you to contact us for a pump solution if have any demand.

Contact person: Mr. Luke

Tel: +86-574-87769810 Fax: +86-574-62962898

Mobile/Whatsapp/Wechat: +86 13586591843

Email: bvsales3@bonvepumps.com