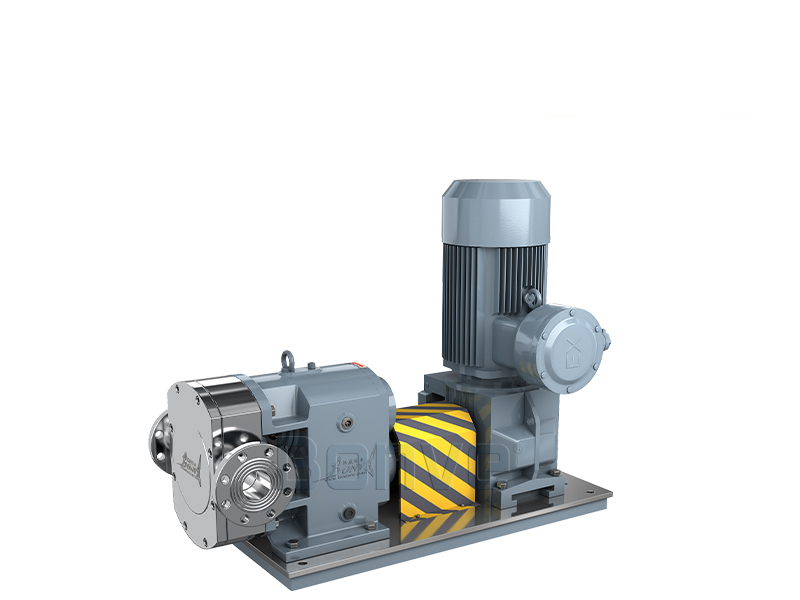

Polymer solutions transfer lobe pump with ATEX motor

Bonve chemical grade rotary lobe pumps are sucessfully to transfer polymer solutions due to the below main features.

- All contact parts (except seal rings) are made of super stainless steel, high corrosion resistance and abrasion resistance.

- Elastic material is PTFE or FFKM, temperature resistance is upto 280C degree.

- Gap is kept between the rotor and rotor, rotor and pump chamber, no friction and long service life.

- Targeted seal structure and material used to make sure no leakage trouble.

- Jacket design to run cold or hot liquid to ensure a consistant pump temperature.

- Effectively to transfer the polymer solutions at different viscosity.

- Low noise, no vibration, energy saving, low maintenance.

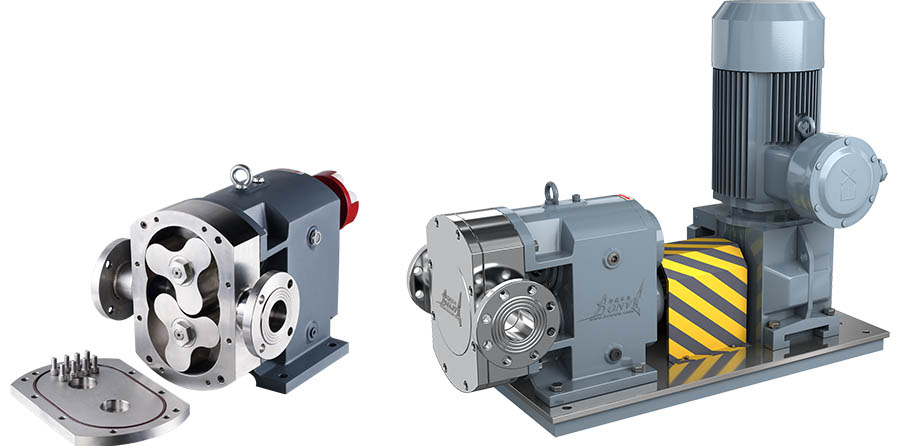

- Simple assembly and disassembly, nearly no wearing parts.

- Pump flow can be adjusted at will by VFD.

- ATEX approved motors.

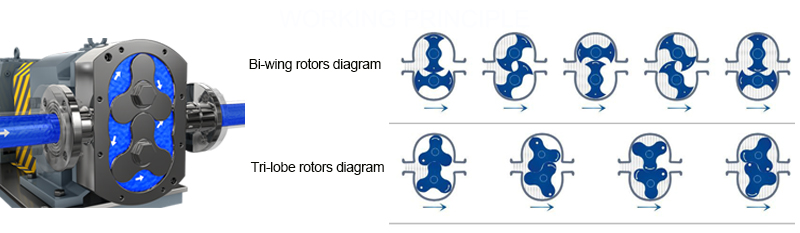

Working Principle

Bonve lobe pumps basically consist of two lobe rotors, which rotate synchronously driven by a pair of synchronous gears in the gearbox. The rotors are driven by the main shaft and sub-shaft to rotate in a synchronous reverse direction, which changes the pump capacity, builds up high vacuum and discharge pressure, thus an efficient pumping is formed. Gap is kept between the rotors and between the pump casing, no friction, long life, no damage, no physical and chemical reaction to the pumped products.

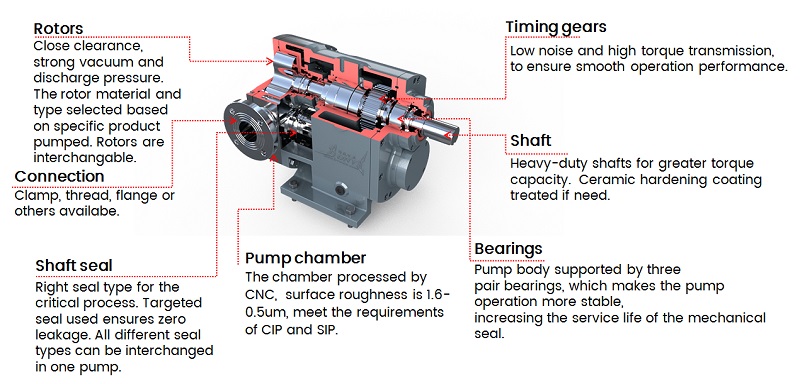

What the Bonve lobe pump structure advantage?

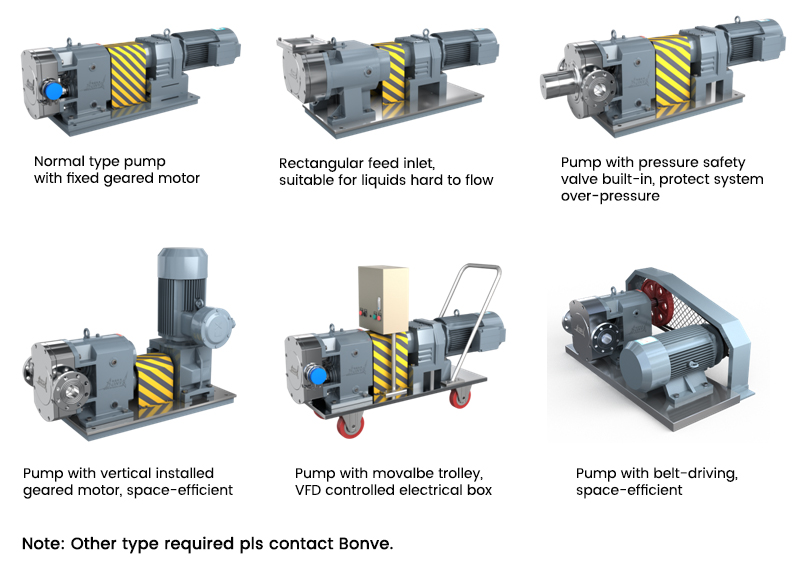

Pump Types

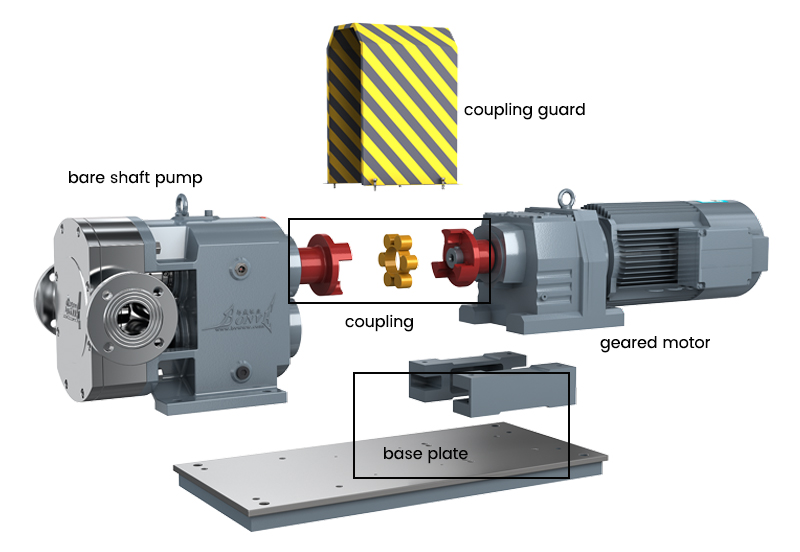

Bonve complete pump components

Pumps Technical Parameters

|

Model |

Displace -ment |

RPM |

Flow rate |

Dis. Pre. |

Power |

Vacuum |

Port size |

Max viscosity |

|

(L/r) |

(r/min) |

(m³/h) |

(Mpa) |

(kW) |

(Mpa) |

(mm) |

(cp) |

|

|

25BV12-05 |

0.06 |

10-1000 |

0-0.5 |

0-1.2 |

0.37-1.1 |

-0.080 |

25 |

1,500,000 |

|

40BV12-2 |

0.15 |

10-1000 |

0-2 |

0-1.2 |

0.75-2.2 |

-0.080 |

40 |

1,500,000 |

|

50BV12-5 |

0.32 |

10-800 |

0-5 |

0-1.2 |

1.5-4 |

-0.085 |

50 |

1,500,000 |

|

65BV12-10 |

0.65 |

10-600 |

0-10 |

0-1.2 |

2.2-7.5 |

-0.085 |

65 |

1,500,000 |

|

80BV12-20 |

1.74 |

10-500 |

0-20 |

0-1.2 |

4-15 |

-0.095 |

80 |

1,500,000 |

|

90BV12-30 |

2.60 |

10-500 |

0-30 |

0-1.2 |

5.5-22 |

-0.095 |

100 |

1,500,000 |

|

100BV12-40 |

3.65 |

10-500 |

0-40 |

0-1.2 |

7.5-30 |

-0.095 |

100 |

1,500,000 |

|

125BV12-50 |

4.60 |

10-500 |

0-50 |

0-1.2 |

7.5-37 |

-0.095 |

125 |

1,500,000 |

|

140BV12-70 |

6.10 |

10-500 |

0-70 |

0-1.2 |

11-45 |

-0.095 |

150 |

1,500,000 |

|

150BV12-80 |

7.63 |

10-500 |

0-80 |

0-1.2 |

11-55 |

-0.095 |

150 |

1,500,000 |

|

200BV12-120 |

11.56 |

10-400 |

0-120 |

0-1.2 |

15-75 |

-0.095 |

200 |

1,500,000 |

|

250BV12-150 |

14.22 |

10-400 |

0-150 |

0-1.2 |

18.5-90 |

-0.095 |

250 |

1,500,000 |

|

300BV12-200 |

20.80 |

10-300 |

0-200 |

0-1.2 |

22-110 |

-0.095 |

300 |

1,500,000 |

|

350BV12-300 |

32.60 |

10-250 |

0-300 |

0-1.2 |

45-160 |

-0.095 |

350 |

1,500,000 |

|

400BV12-400 |

50.40 |

10-250 |

0-400 |

0-1.2 |

55-200 |

-0.095 |

400 |

1,500,000 |

Note:

1. Tested medium: water. Your liquid's density, viscosity

and temperature are necessary to supply when choose the pump.

2. Speed, flow rate, electrical power and pressure will be

varified according to different liquid properties.

3. Port size can be changed as needed.

Selection Guidelines

|

Your Industry |

|||

|

About transfer liquid |

Name: |

||

|

Density (g/m³): |

|||

|

Viscosity (mPa.s): |

|||

|

Temperature (℃): |

|||

|

PH value: |

|||

|

Solid content (%): |

|||

|

Solid size (mm): |

|||

|

Suction side |

Pressure: Positive ( ) bar; Negative ( ) bar |

How high (m): |

|

|

Suction pipe length (m): |

Diameter (mm): |

||

|

Bends (Pcs): |

T-piece (Pcs): |

Valves (Pcs): |

|

|

Discharge side |

Pressure (Mpa): |

||

|

Vertical delivery pipe length (m): Total delivery pipe length (m): |

Diameter (mm): |

||

|

Bends (Pcs): |

T-piece (Pcs): |

Valves (Pcs): |

|

|

Required flow rate (L/H) |

Operating flow: |

Max. flow: |

|

|

Pump material required |

SS304 ( ) SS316 ( ) SS316L ( ) Duplex stainless steel ( ) |

||

|

Motor required |

Phase: Single ( ) Three ( ) |

Voltage (V): |

Frequency (Hz): |

|

IP grade: |

Energy efficiency: |

Anti-explosive: |

|

|

Installation type |

Fixed ( ) |

Movable ( ) |

Fixed with adjusting feet ( ) |

|

Others |

|||

About Us

BONVE is a Chinese leading manufacturer in ROTARY LOBE PUMPS and HOMOGENIZER MIXERS. Providing its customers with customized pumping and mixing solutions and solving their problems during the production.

Bonve pumps and mixers are widely used in food, dairy, beverages, chemical, pulp&paper, soaps&detergents, pharmaceuticals, pesticide, coatings etc. By 2021, Bonve served 4,000+ customers in various industries and 50,000+ pumps running in the worldwide.

Time and again companies specify Bonve pumps as the "standard" equipment for their manufacturing processed. We are looking forward to be partner with you.

Contact Us

We welcome you to contact us for a pump solution if have any demand.

Contact person: Mr. Tom

Mobile/Whatsapp/Wechat: +86 13375846933

Email: trade@bonvepumps.com