Rotary Lobe Pumps For Polyol

Rotary Lobe Pumps for Polyol, we defined these pumps are Polyol Transfer Pump.

Polyols are a key ingredient in different polyurethane foams. Polyols are alcohols that have many hydroxyl radicals. Viscosity varies across different polyols and can be as thick as 40000 centipoise.

Polyols are often blended with isocyanates, so pumps handing polyols are often built using isocyanate compatible lubricants and required non-pulsating flow to ensure a proper mixing ratio. Polyols can also be mixed with polymer solids to enhance the properties of the foam produced when blended with isocyanates, which can necessitate abrasive resistant construction.

Reasons to Choose Bonve Rotary Lobe Pump

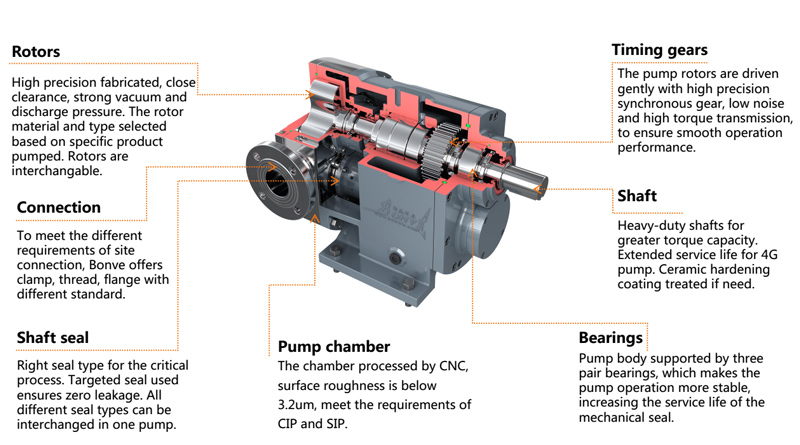

Bonve is an experienced polyol transfer pump manufacturer, which has served several polyol customers. The core components of lobe pump are processed by CNC maching center, which has th characteristics of high precision, high bending strength and strong wear resistance. The seal material and type of bonve rotary lobe pump are selected according to the characteristics of the pumped product, to ensure zero leakage, no pollution, and more environmental protection. Six bearings arranged in a separate arrangement increase the concentricity of the pump operation, enhance the bearing capacity of the shaft and make the pump running more stable, thereby increasing the service life of the shaft and the mechanical seal. These characteristics improve the stability of customers when handling with polyols.

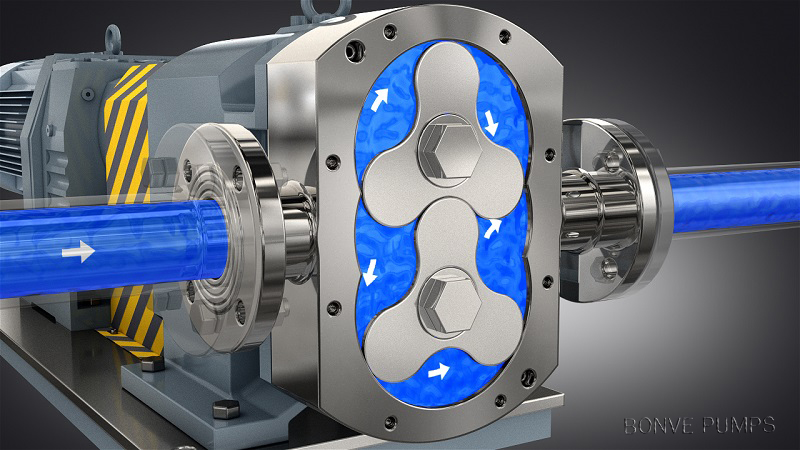

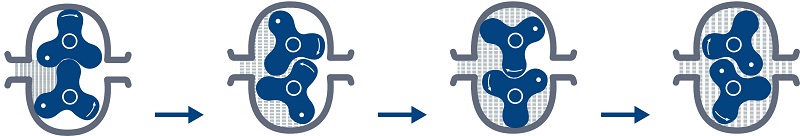

Working Principle

Bonve lobe pumps basically consist of two lobe rotors, which rotate synchronously driven by a pair of synchronous gears in the gearbox. The rotors are driven by the main shaft and sub-shaft to rotate in a synchronous reverse direction, which changes the pump capacity, builds up high vacuum and discharge pressure, thus an efficient pumping is formed. Gap is kept between the rotors and between the pump casing, no friction, long life, no damage, no physical and chemical reaction to the pumped products.

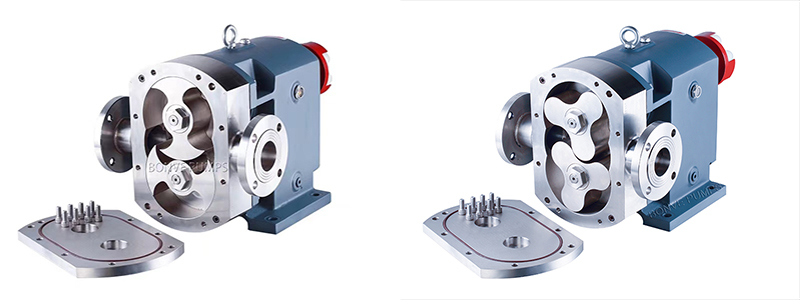

Bi-wing rotor diagram

Tri-lobe rotors diagram

Structure Details

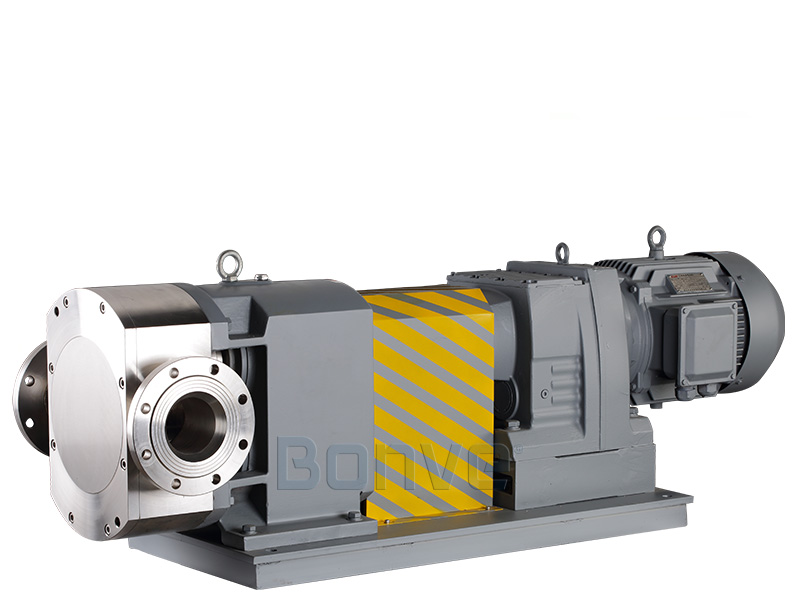

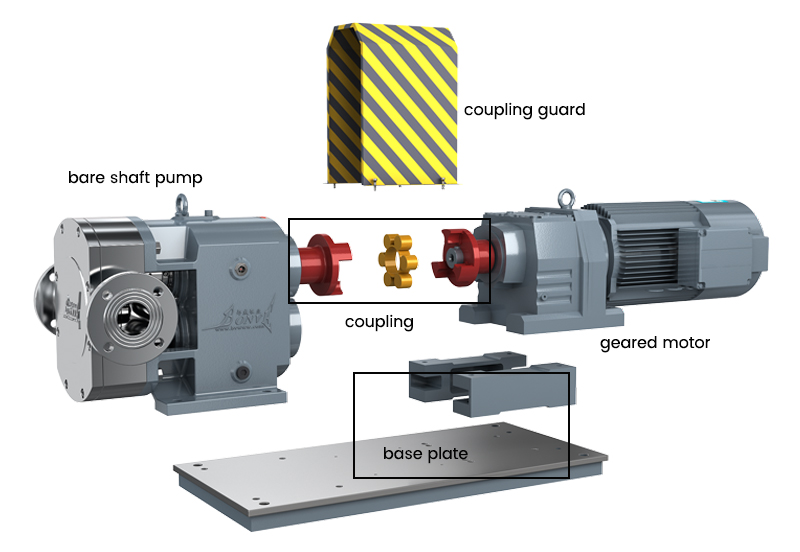

Complete Pump Structure

Bonve complete pumps are usually composed of bare shaft pump, coupling and its guard, geared motor and baseplae. With your order, bare shaft pump or complete pump is supplied.

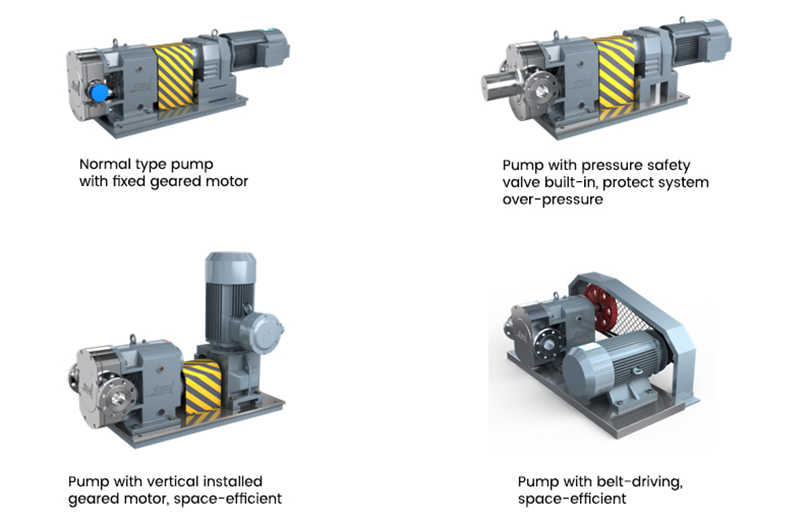

Complete Pump Types

Pump Technical information at glance

Performance

• Flow rate up to approx. 500,000 l/h

• Operation pressure up to 15 bar

• Suction head up to 9 mWC

• Product Viscosity: Up to 1,000,000 mPas

• Temperature Resistance: up to 250°C

• PH: 1-14

Design Structure

• Rotor type: Single-wing Rotors, Bi-wing(Butterfly)Rotors, Tri-lobe Rotors, Multi-impeller Rotors

• Seal type: Single-face Balanced Mechanical Seal, Double-face Water-cooled Machine Seal, Metal Bellows Mechanical Seal

• Flow direction: left↔ right, up↔ down

• Port connection: Clamp, thread and flange in different standards

• Installation type: Fixed, fixed with adjustable feet, mobile

• Pump Colors: Blue, Grey, White

• Heating or cooling jacket as per request

• Driving type: Fixed speed geared motor, variable speed geared motor, , Further materials on request

Materials

• Pump housing and cover: stainless steel AISI 316, 316L

• Mechanical Shaft Seals: Tungsten carbide, Silicon carbide, Further materials on request

Sealing Materials of O-rings: Viton, EPDM, Further materials on request

Technical Parameters

|

Model |

Displace -ment |

RPM |

Flow rate |

Dis. Pre. |

Power |

Vacuum |

Port size |

Max viscosity |

|

(L/r) |

(r/min) |

(m³/h) |

(Mpa) |

(kW) |

(Mpa) |

(mm) |

(cp) |

|

|

25BV12-05 |

0.06 |

10-1000 |

0-0.5 |

0-1.2 |

0.37-1.1 |

-0.080 |

25 |

1,500,000 |

|

40BV12-2 |

0.15 |

10-1000 |

0-2 |

0-1.2 |

0.75-2.2 |

-0.080 |

40 |

1,500,000 |

|

50BV12-5 |

0.32 |

10-800 |

0-5 |

0-1.2 |

1.5-4 |

-0.085 |

50 |

1,500,000 |

|

65BV12-10 |

0.65 |

10-600 |

0-10 |

0-1.2 |

2.2-7.5 |

-0.085 |

65 |

1,500,000 |

|

80BV12-20 |

1.74 |

10-500 |

0-20 |

0-1.2 |

4-15 |

-0.095 |

80 |

1,500,000 |

|

90BV12-30 |

2.60 |

10-500 |

0-30 |

0-1.2 |

5.5-22 |

-0.095 |

100 |

1,500,000 |

|

100BV12-40 |

3.65 |

10-500 |

0-40 |

0-1.2 |

7.5-30 |

-0.095 |

100 |

1,500,000 |

|

125BV12-50 |

4.60 |

10-500 |

0-50 |

0-1.2 |

7.5-37 |

-0.095 |

125 |

1,500,000 |

|

140BV12-70 |

6.10 |

10-500 |

0-70 |

0-1.2 |

11-45 |

-0.095 |

150 |

1,500,000 |

|

150BV12-80 |

7.63 |

10-500 |

0-80 |

0-1.2 |

11-55 |

-0.095 |

150 |

1,500,000 |

|

200BV12-120 |

11.56 |

10-400 |

0-120 |

0-1.2 |

15-75 |

-0.095 |

200 |

1,500,000 |

|

250BV12-150 |

14.22 |

10-400 |

0-150 |

0-1.2 |

18.5-90 |

-0.095 |

250 |

1,500,000 |

|

300BV12-200 |

20.80 |

10-300 |

0-200 |

0-1.2 |

22-110 |

-0.095 |

300 |

1,500,000 |

|

350BV12-300 |

32.60 |

10-250 |

0-300 |

0-1.2 |

45-160 |

-0.095 |

350 |

1,500,000 |

|

400BV12-400 |

50.40 |

10-250 |

0-400 |

0-1.2 |

55-200 |

-0.095 |

400 |

1,500,000 |

Note:

1. Tested medium: water. Your liquid's density, viscosity

and temperature are necessary to supply when choose the pump.

2. Speed, flow rate, electrical power and pressure will be

varified according to different liquid properties.

3. Port size can be changed as needed.

About Us

BONVE is a Chinese leading manufacturer in ROTARY LOBE PUMPS and HOMOGENIZER MIXERS. Providing its customers with customized pumping and mixing solutions and solving their problems during the production.

Bonve pumps and mixers are widely used in food, dairy, beverages, chemical, pulp&paper, soaps&detergents, pharmaceuticals, pesticide, coatings etc. By 2020, Bonve served 4,000+ customers in various industries and 50,000+ pumps running in the worldwide.

Time and again companies specify Bonve pumps as the "standard" equipment for their manufacturing processed. We are looking forward to be partner with you.

Contact Us

We welcome you to contact us (trade@bonvepumps.com) for a pump solution if have any demand.