Bonve rotary lobe pumps are to be found in numerous processes, where their reliable low shear flow characteristics are ideally suited to the transfer of media such as cream, hair gel, shampoo, conditioners, body lotion and surfactant.

AES (Sodium Alcohol Ether Sulphate) is a colorless, white or Pale yellow viscous liquid, the smell is typical soap taste of the basic anion Surfactant. Bonve offers the broadest range of its rotary lobe pumps with targeted driving to work with AES transportation. We named these pumps are AES transfer pump.

AES has excellent decontamination, emulsification, foaming performance and hard water resistance. Widely used in the preparation of Shampoos, body washes, hand sanitizers, meal detergents, washing liquid, washing powder and other daily chemical products. Also used in the preparation of hard surface cleaning agents such as glass cleaner and car cleaner. Used in combination with K12, LAS-Na, 6501, etc. Bonve AES lobe pumps play an important role in these applications. Let's go for more details about the pump.

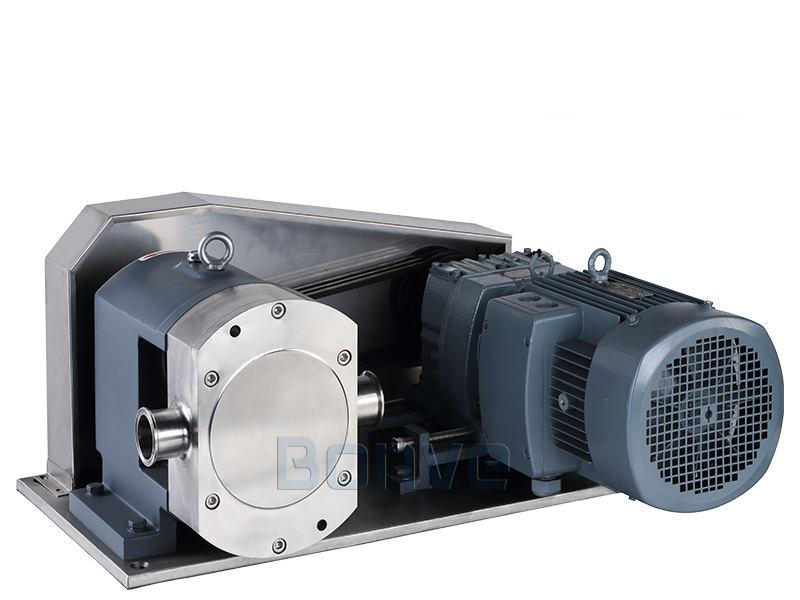

PUMP TECHNICAL FEATURES

- Displacement: positive displacement, Displacement is proportional to the speed. Max. Capacity is upto 300m3/h.

- Discharge pressure: upto 1.2Mpa.

- Suction capacity: Upto -0.095Mpa under flooded condition.

- Work efficiency: upto 90%

- Special mediums to handle: high viscosity upto 1.5million cps, high solid mediums upto 60%, sensitive mediums.

- Dry running: with Bonve's special design on mechanical seal, dry running can be realized.

- Maintenance: Compact structure, little space occupation, no need to move pipe systems when maintain.

- Wear-resisting: all the contact parts are made of stainless steel. Nearly no wearing parts.

- Low shearing: Low working speed, gap is kept between the rotors and between the rotor and the pump body, no friction,long life.

- Replacement: take replace of screw pumps, gear pumps, centrifugal pump,diaphragm pump etc.

- Low cost: high working efficiency, low consumption, environmental friendly, low maintenance, long life.

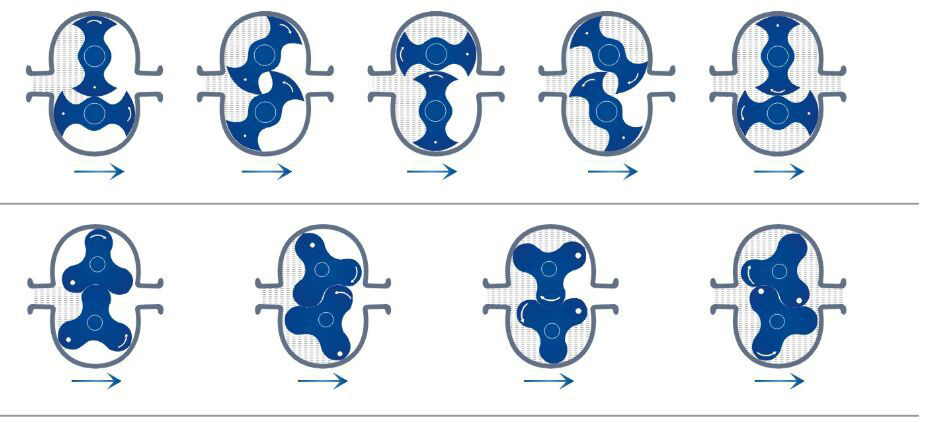

PUMP WORKING PRINCIPLE

Bonve AES Lobe pumps are of conventional design operating with no internal contacting parts in the pump head. The pumping principle is explained with reference to the diagram below, which shows the displacement of fluid from pump inlet to outlet. The rotors are driven by a gear train in the pump gearbox providing accurate synchronisation or timing of the rotors. The rotors contra-rotate within the pump head carrying fluid through the pump, in the cavities formed between the dwell of the rotor and the interior of the rotorcase.

In hydraulic terms, the motion of the counter rotating rotors creates a partial vacuum that allows atmospheric pressure or other external pressures to force fluid into the pump chamber. As the rotors rotate an expanding cavity is formed which is filled with fluid. As the rotors separate, each dwell forms a cavity. The meshing of the rotor causes a diminishing cavity with the fluid being displaced into the outlet port.

PUMP STRUCTURE ADVANTAGES

PUMP TECHNICAL PARAMETERS

|

Model |

Displacement |

RPM |

NormalFlow |

Dis.Pre. |

Power |

Port size(mm) |

|

|

|

(L/r) |

(r/min) |

(M³/h) |

(Mpa) |

(kW) |

Stand. |

Enlarged |

|

25BV12-05 |

0.06 |

10-1000 |

0-0.5 |

0-1.2 |

0.37-1.1 |

15 |

25 |

|

40BV12-2 |

0.15 |

10-1000 |

0-2 |

0-1.2 |

0.75-2.2 |

25 |

40 |

|

50BV12-5 |

0.32 |

10-800 |

0-5 |

0-1.2 |

1.5-4 |

40 |

50 |

|

65BV12-10 |

0.65 |

10-600 |

0-10 |

0-1.2 |

2.2-7.5 |

50 |

65 |

|

80BV12-20 |

1.74 |

10-500 |

0-20 |

0-1.2 |

4-15 |

65 |

80 |

|

90BV12-30 |

2.60 |

10-500 |

0-30 |

0-1.2 |

5.5-22 |

80 |

100 |

|

100BV12-40 |

3.65 |

10-500 |

0-40 |

0-1.2 |

7.5-30 |

80 |

100 |

|

125BV12-50 |

4.60 |

10-500 |

0-50 |

0-1.2 |

7.5-37 |

100 |

125 |

|

140BV12-70 |

6.10 |

10-500 |

0-70 |

0-1.2 |

11-45 |

125 |

150 |

|

150BV12-80 |

7.63 |

10-500 |

0-80 |

0-1.2 |

11-55 |

125 |

150 |

|

200BV12-120 |

11.56 |

10-400 |

0-120 |

0-1.2 |

15-75 |

150 |

200 |

|

250BV12-150 |

14.22 |

10-400 |

0-150 |

0-1.2 |

18.5-90 |

150 |

250 |

|

300BV12-200 |

20.80 |

10-300 |

0-200 |

0-1.2 |

22-110 |

200 |

300 |

|

350BV12-300 |

32.60 |

10-250 |

0-300 |

0-1.2 |

45-160 |

300 |

350 |

|

400BV12-350 |

50.40 |

10-250 |

0-350 |

0-1.2 |

55-200 |

350 |

400 |

Note:

1. Tested medium: water. Your liquid's density, viscosity and temperature are necessary to supply when choose the pump.

2. Speed, flow rate, electrical power and pressure will be varified according to different liquid properties.

3. Port size can be changed as needed.

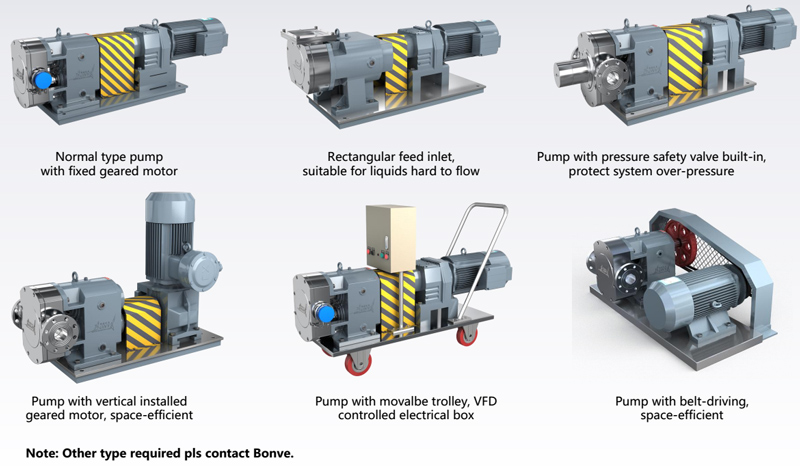

PUMP TYPES

PUMP SELECTION GUIDELINE

|

Liquid information |

|

Your industry: __________ Liquid name:___________ |

|

Features: Sanitary [ ] Corrosive [ ] Poisonous [ ] |

|

Viscosity:_______cp Density:_______ Temperature:_____℃ PH value:________ |

|

Solid content:_______ Max. size of particle:_______ |

|

Using condition |

|

Capacity: Max. required__________ L/H Working required__________ L/H |

|

Discharge pressure: Max. required__________Mpa Working required__________ Mpa |

|

Suction pressure: Max. required__________Mpa Working required____________ Mpa |

|

Delivery head required:____________ Vacuum:________ Mpa |

|

Heating jacket required: Yes [ ] No. [ ] Heating temp.:_____℃ |

|

Liquid inlet/outlet direction: Horizontal [ ] vertical [ ] |

|

Pipe size: Inlet___________ Outlet____________ |

|

Connection type required: Flange [ ] Thread [ ] Clamp [ ] |

|

Installation type: Fixed [ ] Movable [ ] |

|

Operating status: Continuous [ ] Interruption [ ] |

|

Liquid contact material: SS304 [ ] 316[ ] 316L [ ] Others________ |

|

Special request_____________________________________ |

|

Order qty. |

* For a quick quote, please email cathy@bonvepumps.com to ask form and fill. As a professional manufactrurer of AES lobe pump more than 18 years experience, hope we can work with you and solve your pumping problem.