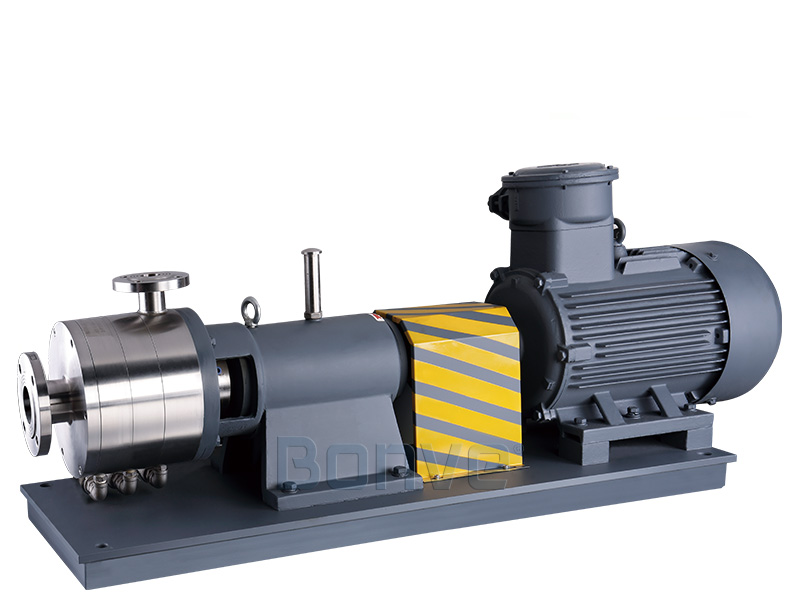

Bitumen homogenizer with explosion-proof motor

Bonve offers the broadest tange of its homogenizer mixers for bitumen application. Over the years, Bonve has been focused on communication with customers and constantly optimize our mixers to be low maintenance, long-life cycle and environmental friendly. We select the homogenizer according to your characteristics of medium and condition of the technological requirements, bring you the best homogenizer for your critical process, satisfied by you and your customers.

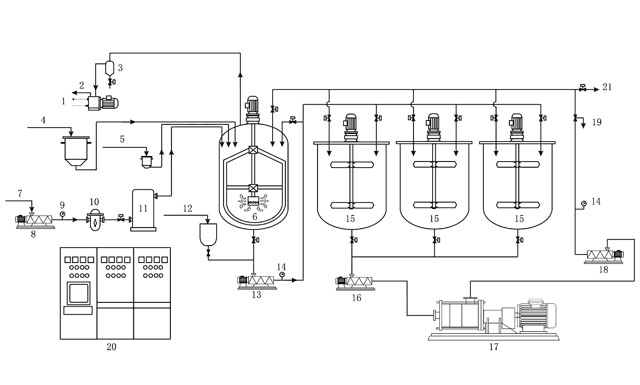

Typical process for modified bitumen/asphalt

1. Channel for cooling water 2. Evacuation 3. Knock out drum 4. Modifier 5. Stablilizer 6. Make-up tank 7. Heated asphalt

8. Feed pump 9. Manometer 10. Filter 11. Heat exchanger 12. Liquid additives 13. Circulating pumps 14. Electro connecting

pressure gauge 15. Asphalt expansion tank 16. Pitch adjustment pump 17. 3-stage inline homogenizer mixer 18. Discharging

pump 19. Sample valve 20. Computer Control System 21. Finished products

Bonve Homogenizer Mixer

Bonve Homogenizer Mixer is an efficient type machine with mixing, dispersion, breaking, dissolution, refinery, homogenization and emulsifying. It is an ideal machine to be instead of colloid mill, ball mill and high pressure homogenizer. The machine can greatly simplify the traditional productions and upgrade the production efficiency and product quality.

HOW IT WORKS?

The main parts are stators and rotors. At centrifugal and fluid forces created by rapid turning of the rotors, the stators exercise on the materials with strong power shearing, centrifugal pressing, breaking, fluid friction, turbulent. The processed materials (solid, fluid and gas phase) are quickly refined, homogenized, dis-aggregated and emulsified. The repeat of this process can result in stable and high-quality products.

MIAN TECHNICAL FEATURES

-Capacity: Self-pumping through puts of up to 130 T/H.

-No Bypassing: Product cannot bypass the precision rotor/stator work head.

-Work heads: Three stages rotors/stators.

-Materials of Construction: SS304, SS316 and 316L.

-Motor Specification: Explosion-Proof Motor. Standard power supply: 3ph, 380V, 50Hz.

-Inlet and Outlet Connections: Flange connection as standard.

-Sealing: Double-face water flushed mechanical shaft seals as standard.

-Jacket: Desinged for Heating medium oil with temperature 180-200 Celcius.

TECHNICAL PARAMETERS FOR REFERENCE

|

Model |

Electrical Power (Kw) |

Rotation Speed (r/min) |

Handling Capacity (m3/h) |

Discharge pressure (Mpa) |

Dia. of inlet/outlet (mm) |

|

FHM3/140 |

11 |

2900 |

5 |

0.2 |

DN40/32 |

|

FHM3/165 |

18.5 |

2900 |

10 |

0.3 |

DN50/40 |

|

FHM3/185 |

30 |

2900 |

20 |

0.4 |

DN65/50 |

|

FHM3/200 |

45 |

2900 |

30 |

0.5 |

DN80/65 |

|

FHM3/220 |

55 |

2900 |

40 |

0.5 |

DN80/65 |

|

FHM3/240 |

90 |

2900 |

60 |

0.6 |

DN100/80 |

|

FHM3/260 |

132 |

2900 |

100 |

0.6 |

DN125/100 |

SELECTION GUIDELINE

|

Your industry/application |

|

|

Processed medium's name |

|

|

Medium's proportion |

Liquid % ____ Density____ Viscosity____ PH value____ Solid % ____ Solid size ___ |

|

Processing requirement |

Mixing dissolving ( ) Dispersed suspension ( ) Emulsification ( ) Homogeneity ( ) Reaction ( ) Powder liquid mixing ( ) |

|

Working type |

Continuous circulation work ( ) Batch type ( ) |

|

Working temperature |

|

|

Particle size |

Before processing ____ After processing _____ |

|

Handling capacity required |

|

|

Delivery head/pressure required |

|

* For a quick quote, please email cathy@bonvepumps.com to ask form and fill. Thank you for your interest into our bitumen homogenizer.