Beyond Price: The Real Cost of Choosing a Pump for Concentrated Juice

Let's be honest. In my role as a Procurement Manager, the price tag is often the first thing I see. My job is to manage costs. But a recent disaster with a "cost-effective" pump that failed to handle our 70° Brix mango puree—grinding our line to a halt for a full shift—taught me a brutal lesson.

The real cost of a pump isn't its purchase price. It's the total impact on my product quality, my production schedule, and my bottom line.

If you're sourcing a transfer pump for concentrated juices, syrups, or purees, looking beyond the initial quote is critical. Here are the three non-negotiable areas I now scrutinize, based on hard-won experience.

1. The Silent Product Killer: Shear Stress

You've invested heavily in evaporators and technology to concentrate the very essence of the fruit. Why would you let a pump undo all that work?

The Problem: Many pumps, especially high-speed centrifugals, operate like blenders. They rip apart the delicate cellular structure of the fruit. This "shearing" action destroys the fresh flavor notes, dulls the vibrant color, and can cause separation. The result? A final product that tastes cooked or processed, even before it's pasteurized.

The Question I Now Ask: "Can you demonstrate your pump's low-shear performance? Do you have a case study showing flavor preservation or Brix level stability?"

A pump that protects your product isn't an expense; it's an insurance policy for your brand's reputation.

2. The Hygiene Labyrinth: Cleanability is King

Concentrated sugar is a breeding ground for microbes. Any hidden cavity, seal, or dead zone in a pump is a sanitation risk and a QA nightmare.

The Problem: Complex pumps with many parts and tight tolerances are impossible to clean thoroughly. Manual tear-downs for cleaning are labor-intensive and create downtime. If your pump can't handle a rigorous Clean-In-Place (CIP) cycle, you're risking contamination and production delays.

The Question I Now Ask: "Show me the fluid path. Where are the dead legs? What is your Ra surface finish (I look for < 0.8 µm), and is it certified to sanitary standards like 3-A?"

A hygienic design isn't just about passing audits; it's about maximizing uptime and ensuring consumer safety.

3. The True Bottom Line: Total Cost of Ownership (TCO)

That cheap pump might look good on the procurement report, but what does it cost you over two years?

The Problem: A low-quality pump guzzles energy struggling with high viscosity. Its seals wear out quickly from abrasion. Unplanned downtime for repairs and the constant cost of replacement parts can dwarf the initial "savings."

The Calculation I Now Make: I evaluate Total Cost of Ownership:

Initial Purchase Price (the easy part)

Energy Consumption (how efficient is it under load?)

Maintenance & Parts (how often do seals/rotors need changing? How easy is it to service?)

Production Downtime (this is the giant, often hidden cost)

A slightly more expensive pump that runs efficiently for 20,000 hours with minimal downtime and easy CIP is, without a doubt, the cheaper option.

Why Bonve is your right lobe pump manufacturer to choose?

Bonve fabricates its sanitary lobe pumps in strict compliance with EHEDG guidelines and 3-A Sanitary Standards.

Hygienic-Centric Product Design: Avoiding Contamination Risks

- Streamlined, Dead-Corner-Free Pump Chamber: The inner cavity adopts a smooth, curved structure (without sharp edges or blind holes) that allows cleaning fluids (or steam) to flow evenly during CIP (Clean-in-Place) and SIP (Sterilize-in-Place) processes—eliminating hidden spots where bacteria or residues might accumulate.

- Food-Grade Sealing Solutions: We use seals certified by FDA. These seals are resistant to high temperatures (suitable for SIP) and chemical cleaning agents, while preventing fluid leakage or "cross-contamination" between the pump’s moving parts and the transferred medium.

- Quick-Disassembly Structure: Key components (such as lobes, seals, and pump covers) can be disassembled without special tools. This not only simplifies manual inspection and maintenance but also ensures that every part can be thoroughly cleaned—critical for industries like infant food or injectable pharmaceuticals where even minimal contamination is unacceptable.

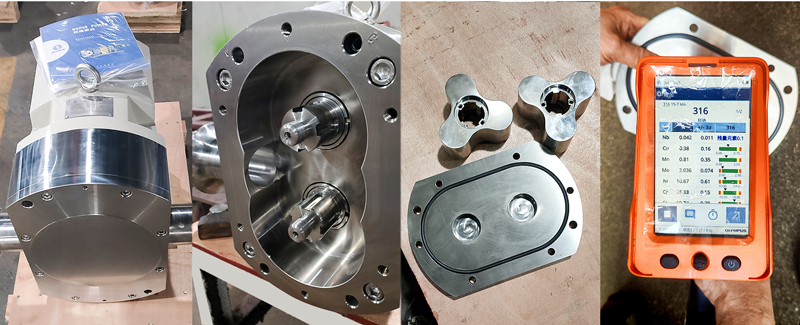

High-Quality Hygienic Materials: From Source to Safety

- The materials of our pumps are carefully selected to meet hygienic-grade durability and safety:

- 316/316L Stainless Steel for Wetted Parts: All parts that come into contact with the transferred fluid (lobes, pump body, inlet/outlet ports) are made of 316/316L stainless steel.

- Surface Finish Meeting Ra ≤ 0.8μm: The inner surface of the pump chamber is polished to a roughness of Ra ≤ 0.8μm. This ultra-smooth surface not only reduces fluid friction (protecting shear-sensitive media like yogurt or biological slurries) but also prevents residues from adhering—making cleaning faster and more thorough.

About BONVE

Top quality lobe pump manufacturer since 2001 | Pump solution supplier for high viscosity liquid

- 25+ Years of Expertise: Reliable technology and experience since 2001.

- Full-chain In-house Control: Independent design, R&D, and production with traceable quality.

- High-precision CNC Manufacturing: Guarantees product accuracy and consistency.

- Flexible Customization (OEM/ODM): Low MOQ options and competitive factory-direct pricing.

- Efficient Capacity & Delivery: 350+ units monthly output; 7-day lead time for standard pumps.

- Professional Seal Solutions: Expertly customized sealing systems—matched to media and conditions—for leak-free and safe operation.

- Full-cycle Technical Support: Senior sales engineers provide end-to-end guidance from design to project completion.

What are the critical advantaged of Bonve lobe pump to transfer high viscous products?

Special bearings tructure

The inner gear box is designed with six separately arranged bearing structures (each shaft has three bearings), so that the shaft is stressed at three points in one, and then processed by high-precision equipment, so that the rotor and the pump body have no friction coefficient.

This design greatly increases the concentricity of the pump operation, enhance the bearing capacity of the shaft and make the structure more stable, thereby increasing the service life of the shaft, the mechanical seal and complete pump.

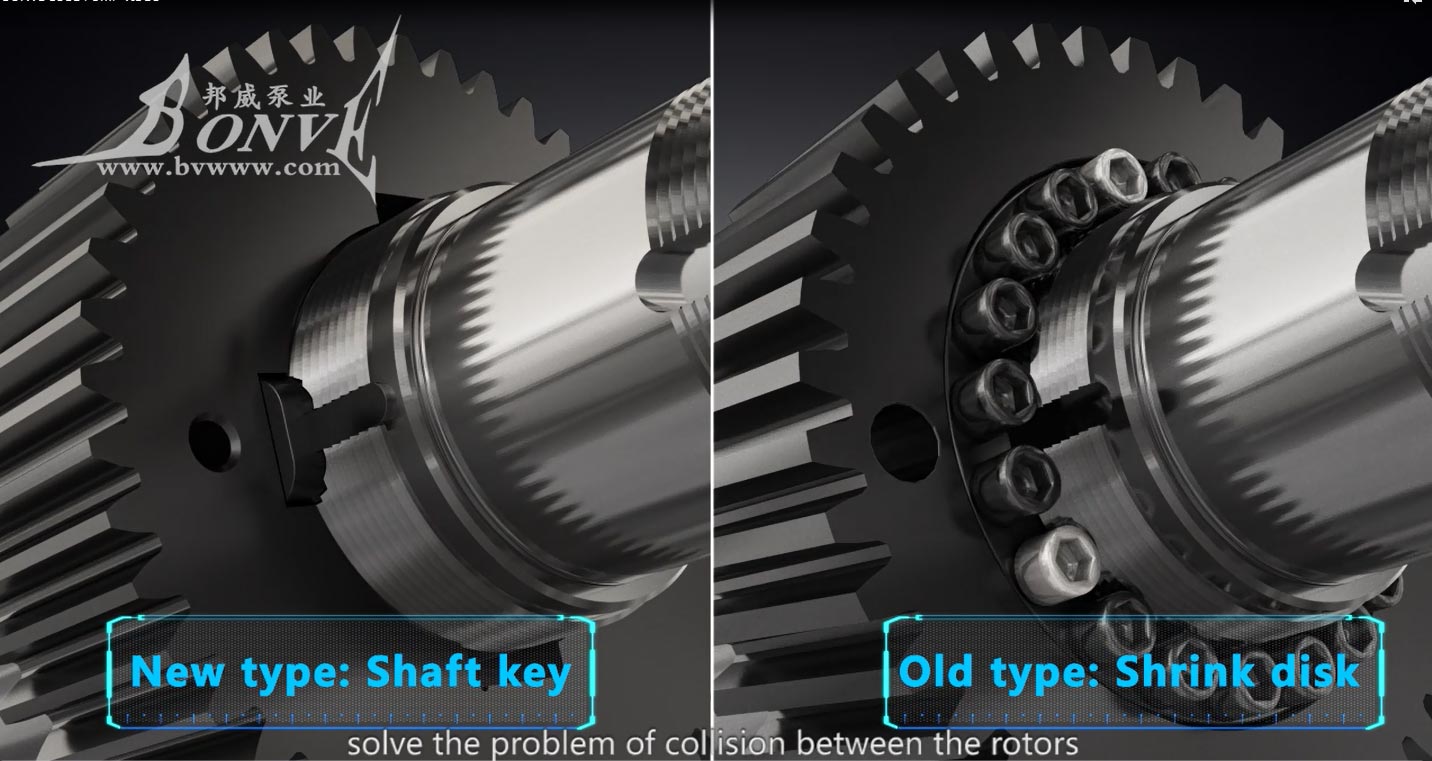

Special shaft fixing way

The combination of synchronous gear and shaft adopts key structure design to replace of shrink disk, so as to avoid the phenomenon of gear slipping or rotor collision when the pump is under high pressure, high viscousity and instant start.

More details about concentrated juice lobe pump, pls click the below pump picture.