When a Sticky Situation Becomes a Costly One?

Your condensed milk line is running, producing that perfect, viscous, and sweet product. Suddenly, a pump fails. The high-sugar content causes the product to crystallize and stick in the lines. The cleanup is a nightmare, the downtime is expensive, and the risk of batch loss is high.

For anyone responsible for procuring equipment in the dairy industry, this isn't just a hypothetical—it's a real operational risk. Your condensed milk transfer pump is a critical piece of infrastructure. Its performance doesn't just move product; it protects your signature texture, ensures consistent quality, and safeguards your profitability.

This guide cuts through the complexity. We'll provide a clear, actionable framework for selecting a pump that handles the unique challenges of condensed milk, helping you make a decision that ensures reliability and protects your product.

1. Why Condensed Milk is a Uniquely Demanding Application?

Condensed milk isn't just "thick milk." Its high sugar content (typically 40-45%) creates specific challenges that rule out most standard pumps.

Extreme Viscosity & High Brix:

The intense thickness demands a pump capable of handling high-viscosity fluids with high suction capability and stable flow, without cavitation.

Sugar Crystallization & Abrasion:

In sweetened condensed milk, existing sugar crystals can be abrasive. A pump must handle this gently to avoid further crystal breakdown (affecting quality) and excessive wear (affecting maintenance costs).

Product Sticking & Hang-up:

The sticky nature of condensed milk means internal pump cavities must be designed to be fully swept and self-draining to prevent product buildup, which is a hygiene hazard.

Shear Sensitivity:

While less shear-sensitive than some dairy products, excessive mechanical shear from the wrong pump can still negatively impact viscosity and mouthfeel.

Hygiene and CIP:

Sticky residues are difficult to clean. The pump must be designed for highly effective and efficient Clean-in-Place (CIP) processes, adhering to 3-A hygienic standards.

2. The Buyer's Checklist: 4 Critical Dimensions for Selection

Dimension 1: Pump Technology – The Foundation of Performance

For condensed milk, Positive Displacement Pumps are the only serious choice. Specifically, Sanitary Rotary Lobe Pumps stand out because they are:

Built for Viscosity: Excel at moving thick products efficiently.

Low-Shear: Gentle on the product, preserving its physical properties.

Controlled Flow: Provide a consistent, non-pulsating transfer vital for filling and packaging.

Dimension 2: Materials & Hygienic Design – Non-Negotiable for Safety

The pump's construction is your first line of defense for food safety.

Wetted Parts: Must be 316L Stainless Steel for all product contact surfaces.

Surface Finish: A superior mirror polish (Ra < 0.8 µm) is crucial to prevent sticky condensed milk from adhering to surfaces and to allow for perfect cleaning.

Seals: Must be FDA-compliant elastomers (like EPDM or FKM) suitable for high-sugar products and CIP chemicals.

Certifications: Insist on 3-A Symbol Authorization to guarantee the hygienic design.

Dimension 3: Sealing System – Ensuring Containment and Uptime

The seal is the most common point of failure. For condensed milk, which can crystallize and abrade, this is critical.

Seal Type: A sanitary single mechanical seal is standard. For applications requiring absolute containment or higher pressures, a double mechanical seal is recommended.

Dimension 4: Total Cost of Ownership (TCO) – The True Measure of Value

The sticker price is just the beginning. The real cost is in the pump's entire lifecycle.

TCO = Purchase Price + Installation + Energy Consumption + Maintenance (Parts & Labor) + Cost of Downtime.

A robust, efficient pump may cost more upfront but saves thousands in reduced energy consumption, less frequent parts replacement, and, most importantly, avoided production stoppages.

Selecting the right condensed milk transfer lobe pump is a strategic decision that safeguards your brand's reputation for quality. By focusing on these five areas, you can make a confident, informed choice.

Feeling overwhelmed? We specialise in helping condensed milk producers like you find the perfect pumping solution.

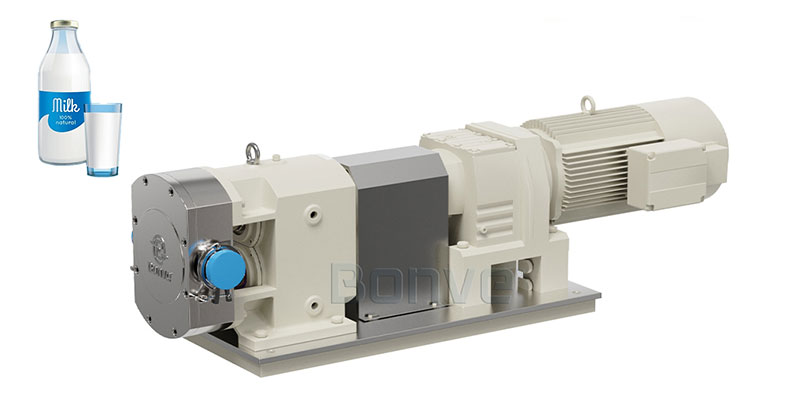

Why Bonve is your right lobe pump manufacturer to choose?

Bonve fabricates its sanitary lobe pumps in strict compliance with EHEDG guidelines and 3-A Sanitary Standards.

Hygienic-Centric Product Design: Avoiding Contamination Risks

- Streamlined, Dead-Corner-Free Pump Chamber: The inner cavity adopts a smooth, curved structure (without sharp edges or blind holes) that allows cleaning fluids (or steam) to flow evenly during CIP (Clean-in-Place) and SIP (Sterilize-in-Place) processes—eliminating hidden spots where bacteria or residues might accumulate.

- Food-Grade Sealing Solutions: We use seals certified by FDA. These seals are resistant to high temperatures (suitable for SIP) and chemical cleaning agents, while preventing fluid leakage or "cross-contamination" between the pump’s moving parts and the transferred medium.

- Quick-Disassembly Structure: Key components (such as lobes, seals, and pump covers) can be disassembled without special tools. This not only simplifies manual inspection and maintenance but also ensures that every part can be thoroughly cleaned—critical for industries like infant food or injectable pharmaceuticals where even minimal contamination is unacceptable.

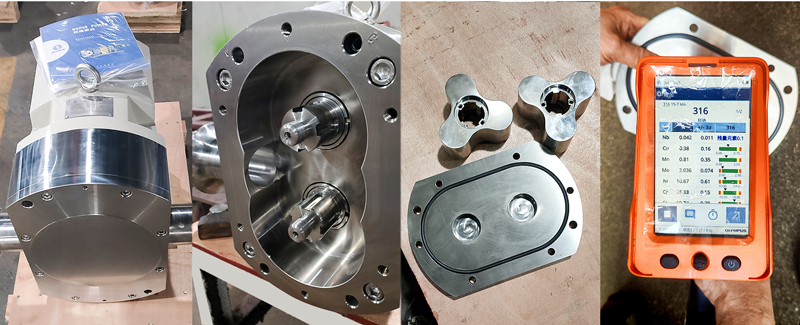

High-Quality Hygienic Materials: From Source to Safety

- The materials of our pumps are carefully selected to meet hygienic-grade durability and safety:

- 316/316L Stainless Steel for Wetted Parts: All parts that come into contact with the transferred fluid (lobes, pump body, inlet/outlet ports) are made of 316/316L stainless steel.

- Surface Finish Meeting Ra ≤ 0.8μm: The inner surface of the pump chamber is polished to a roughness of Ra ≤ 0.8μm. This ultra-smooth surface not only reduces fluid friction (protecting shear-sensitive media like yogurt or biological slurries) but also prevents residues from adhering—making cleaning faster and more thorough.

About BONVE

Top quality lobe pump manufacturer since 2001 | Pump solution supplier for high viscosity liquid

- 25+ Years of Expertise: Reliable technology and experience since 2001.

- Full-chain In-house Control: Independent design, R&D, and production with traceable quality.

- High-precision CNC Manufacturing: Guarantees product accuracy and consistency.

- Flexible Customization (OEM/ODM): Low MOQ options and competitive factory-direct pricing.

- Efficient Capacity & Delivery: 350+ units monthly output; 7-day lead time for standard pumps.

- Professional Seal Solutions: Expertly customized sealing systems—matched to media and conditions—for leak-free and safe operation.

- Full-cycle Technical Support: Senior sales engineers provide end-to-end guidance from design to project completion.

What are the critical advantaged of Bonve lobe pump to transfer high viscous products?

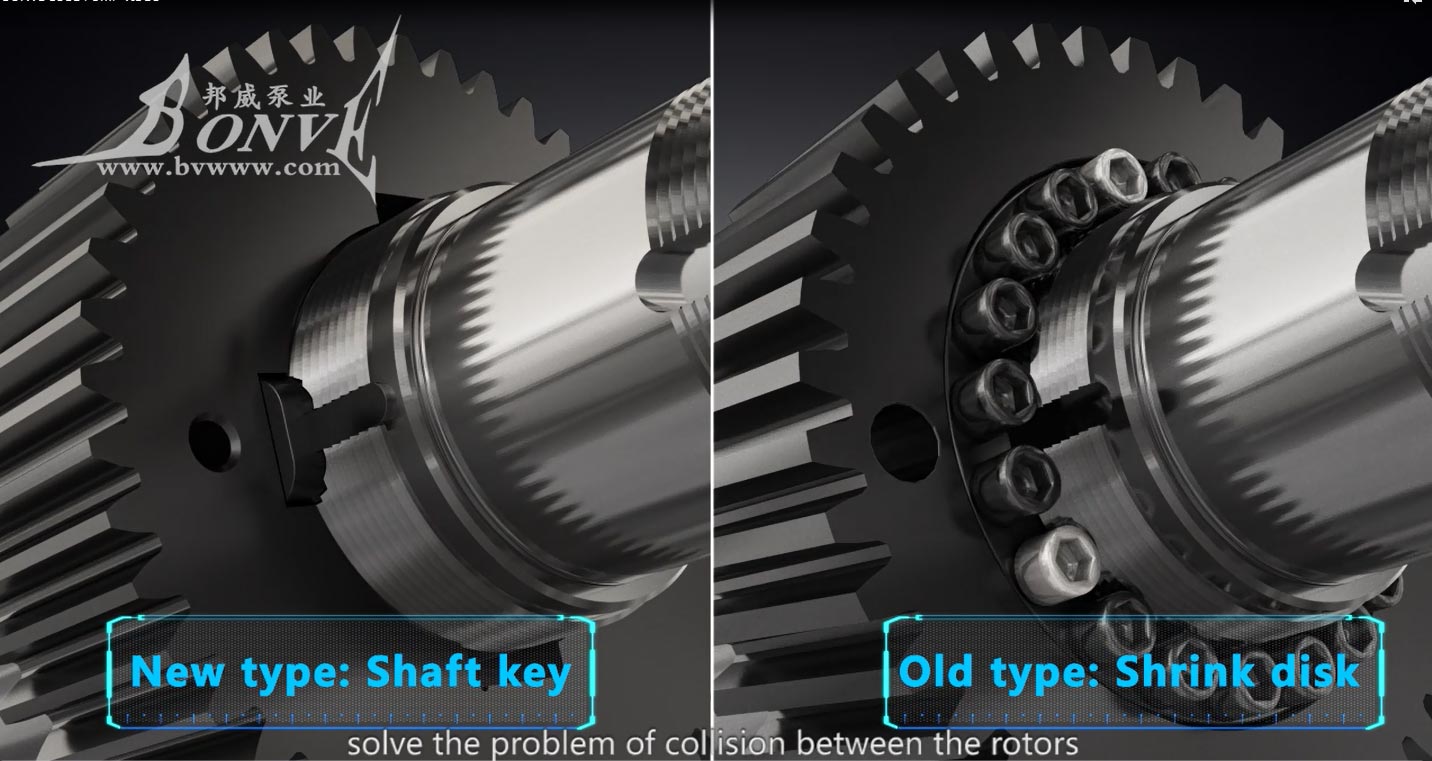

Special bearings tructure

The inner gear box is designed with six separately arranged bearing structures (each shaft has three bearings), so that the shaft is stressed at three points in one, and then processed by high-precision equipment, so that the rotor and the pump body have no friction coefficient.

This design greatly increases the concentricity of the pump operation, enhance the bearing capacity of the shaft and make the structure more stable, thereby increasing the service life of the shaft, the mechanical seal and complete pump.

Special shaft fixing way

The combination of synchronous gear and shaft adopts key structure design to replace of shrink disk, so as to avoid the phenomenon of gear slipping or rotor collision when the pump is under high pressure, high viscousity and instant start.

More details about condensed milk lobe pump, pls click the below pump picture.