Pouring thick honey or squeezing dense ketchup shows how hard it is to move “sticky” substances—even harder on an industrial scale, where gallons of chocolate syrup, motor oil, or yogurt need hourly transfer. Regular pumps often clog, damage products, or fail to move fluids evenly. But lobe pumps solve these issues, making them the top choice for viscous transfers. Here’s why, in simple terms.

First, lobe pump uses a “gentle grabbing” design. Unlike pumps that rely on high pressure or fast parts (which tear or heat viscous products), they have 2-3 rotating “lobes” (soft, curved paddles) in a chamber. The lobes spin in sync but never touch each other or the chamber walls. As they turn, they form sealed pockets that “trap” the product and move it from inlet to outlet—like a conveyor belt for thick fluids. This “positive displacement” ensures consistent flow, no matter how thick the fluid. For example, transferring creamy peanut butter won’t grind its nuts; the lobes keep the texture intact.

Second, they handle clogs and resistance easily. Viscous products push back harder than thin liquids, and regular centrifugal pumps lose power, spin faster, or overheat. Lobe pumps thrive here: their slow, steady rotation generates enough force to move thick fluids without strain. Their wide, smooth internal chambers have no tight gaps, so products like berry jam won’t get stuck—no clogs or backups.

Lobe pump also keeps sensitive viscous products “happy.” Items like cosmetics, dairy, or pharmaceuticals lose quality if heated, mixed roughly, or exposed to air. Lobe pumps offer low shear (no rubbing/tearing, so face cream won’t separate or chocolate burn) and airtight transfer (no bubbles in syrup or lotion). This ensures consistent product quality—critical for most businesses.

Lastly, they’re easy to clean. Viscous fluids like molasses leave tough residues, but lobe pumps have smooth, crevice-free stainless steel surfaces. No hidden spots for buildup, and CIP (Clean-in-Place) systems work fast. You won’t waste time taking pumps apart to scrape dried product.

In short, lobe pumps are ideal for viscous products: gentle, reliable, and kind to both product and workflow. They fix the biggest transfer headaches—no clogs, damage, or inconsistent flow. If regular pumps struggle with your viscous products, a lobe pump isn’t just better—it’s the one that works, every time.

Why Bone is your right lobe pump manufacturer to choose?

- 25+ Years of Expertise: Reliable technology and experience since 2001.

- Full-chain In-house Control: Independent design, R&D, and production with traceable quality.

- High-precision CNC Manufacturing: Guarantees product accuracy and consistency.

- Flexible Customization (OEM/ODM): Low MOQ options and competitive factory-direct pricing.

- Efficient Capacity & Delivery: 350+ units monthly output; 7-day lead time for standard pumps.

- Professional Seal Solutions: Expertly customized sealing systems—matched to media and conditions—for leak-free and safe operation.

- Full-cycle Technical Support: Senior sales engineers provide end-to-end guidance from design to project completion.

What are the critical advantaged of Bonve lobe pump to transfer high viscous products?

Special bearings tructure

The inner gear box is designed with six separately arranged bearing structures (each shaft has three bearings), so that the shaft is stressed at three points in one, and then processed by high-precision equipment, so that the rotor and the pump body have no friction coefficient.

This design greatly increases the concentricity of the pump operation, enhance the bearing capacity of the shaft and make the structure more stable, thereby increasing the service life of the shaft, the mechanical seal and complete pump.

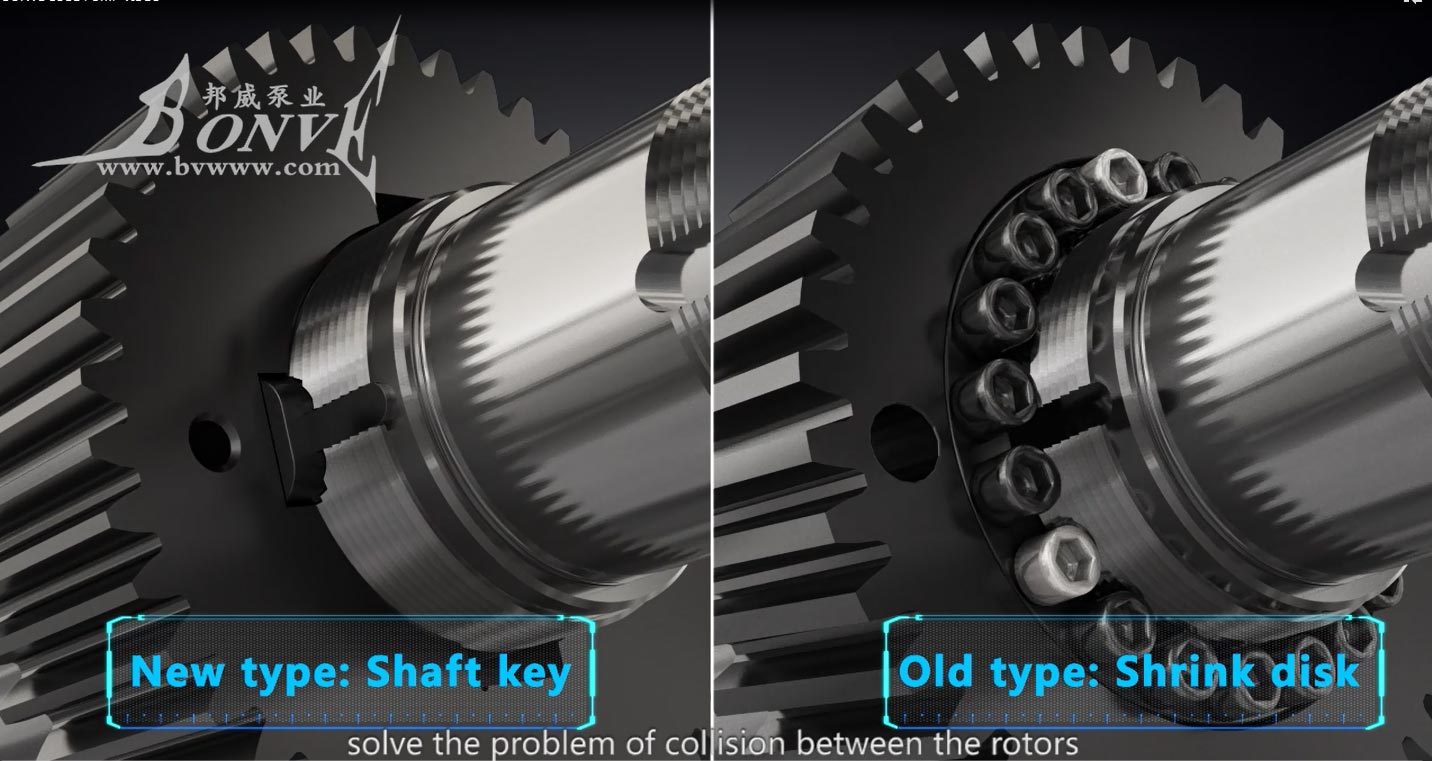

Special shaft fixing way

The combination of synchronous gear and shaft adopts key structure design to replace of shrink disk, so as to avoid the phenomenon of gear slipping or rotor collision when the pump is under high pressure, high viscousity and instant start.