A Beverage Flavor Syrup Producer's Guide to Choosing the Right Transfer Pump

Choosing a pump for your flavor syrups? Don't ruin your perfect recipe with the wrong equipment. Learn the 5 key factors to protect flavor, viscosity, and your bottom line.

Imagine our frustration when a perfectly crafted syrup would occasionally arrive at the filler with a slightly "off" flavor, or a high-potency concentrate would show inconsistent viscosity. The culprit? It wasn't our recipe. It was the pump.

We learned the hard way that a pump is more than a piece of metal that moves liquid. It's the heart of your production line, and choosing the wrong one can silently sabotage your product quality. After extensive research and testing, we've compiled this insider's guide to help you make an informed decision.

Based on our experience, here are the five non-negotiable factors you must consider.

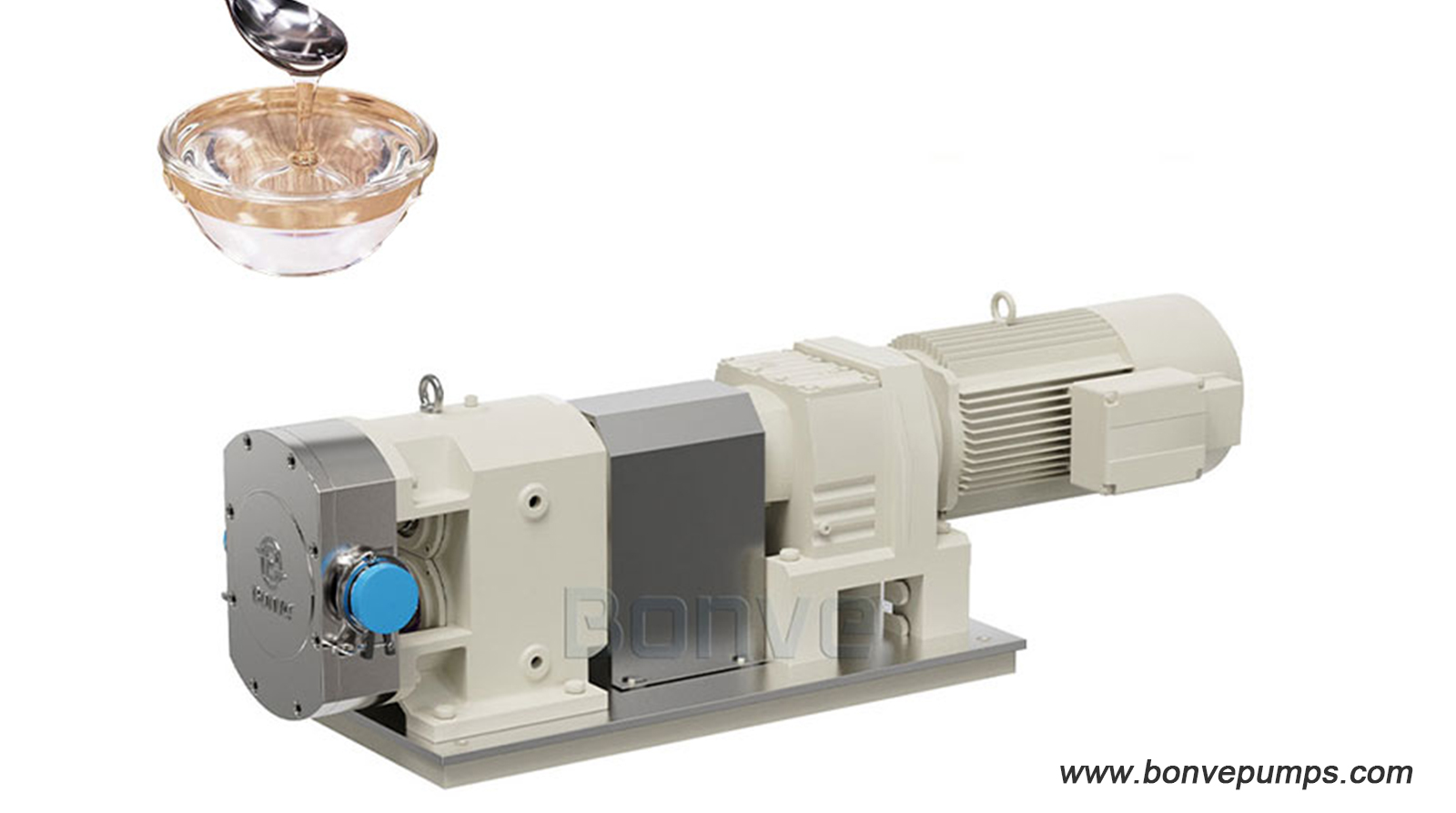

1. Pump Technology: The Gentle Giant vs. The Brutal Bully

Centrifugal Pumps (The Bully): We initially used these. They work by creating velocity, which generates immense shear. They can emulsify your oil-based flavors, crush fruit particulates, and literally beat the air into your product. We do not recommend them for delicate syrups.

Rotary Lobe Pumps (The Gentle Giant): This was our game-changer. These are positive displacement pumps that "cup" the fluid and gently move it. The low-shear action preserves the flavor, texture, and integrity of your most sensitive syrups. It's the difference between a blender and a spoon.

2. Hygienic Design: Your First Line of Defense

This is non-negotiable. Look for:

Materials: 316L or 304 Stainless Steel, electropolished to a mirror finish (Ra < 0.8 µm).

Cleanability: Full CIP (Clean-in-Place) capability is a must. A quick-release, clamp-style casing for manual inspection and cleaning is a huge plus.

Sealing: A well-designed mechanical seal, preferably external to the fluid path, prevents leaks and contamination.

3. Performance That Matches Your Reality

Don't just look at the brochure. Think about your line:

Flow Rate & Pressure: Can it handle your required output and the pressure drop from your filters and long pipe runs?

Viscosity Handling: The pump's performance curve must be stable across your entire product portfolio. High viscosity can dramatically reduce the flow rate of an unsuitable pump.

Self-Priming & Suction Lift: A good self-priming capability offers flexibility in your tank and pump layout.

4. The True Cost of Ownership

The sticker price is a trap. The real cost includes:

Energy Consumption: Efficient pumps save thousands in electricity over their lifespan.

Maintenance & Downtime: How often do seals and rotors need replacement? How long does it take? Easy-to-maintain designs minimize costly production stoppages.

Product Yield: A pump that leaks, cavitates, or is difficult to drain wastes your most valuable asset—your finished product.

5. The Supplier as a Partner

Your pump supplier should be a resource, not just a vendor. Ask:

"Do you have experience in the beverage syrup industry?"

"Can you provide a reference from a similar producer?"

"What does your technical support and parts availability look like?"

Why Bonve is your right lobe pump manufacturer to choose?

Bonve fabricates its sanitary lobe pumps in strict compliance with EHEDG guidelines and 3-A Sanitary Standards.

Hygienic-Centric Product Design: Avoiding Contamination Risks

- Streamlined, Dead-Corner-Free Pump Chamber: The inner cavity adopts a smooth, curved structure (without sharp edges or blind holes) that allows cleaning fluids (or steam) to flow evenly during CIP (Clean-in-Place) and SIP (Sterilize-in-Place) processes—eliminating hidden spots where bacteria or residues might accumulate.

- Food-Grade Sealing Solutions: We use seals certified by FDA. These seals are resistant to high temperatures (suitable for SIP) and chemical cleaning agents, while preventing fluid leakage or "cross-contamination" between the pump’s moving parts and the transferred medium.

- Quick-Disassembly Structure: Key components (such as lobes, seals, and pump covers) can be disassembled without special tools. This not only simplifies manual inspection and maintenance but also ensures that every part can be thoroughly cleaned—critical for industries like infant food or injectable pharmaceuticals where even minimal contamination is unacceptable.

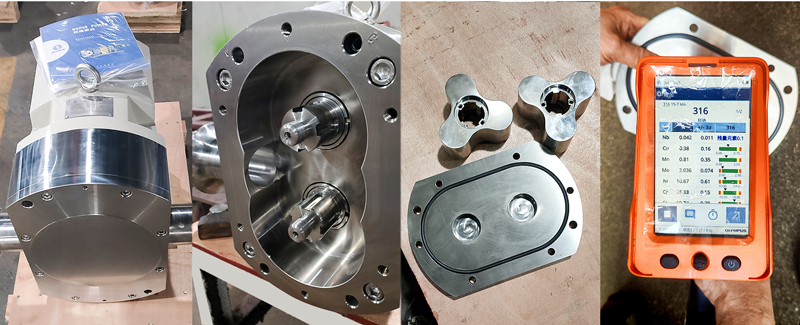

High-Quality Hygienic Materials: From Source to Safety

- The materials of our pumps are carefully selected to meet hygienic-grade durability and safety:

- 316/316L Stainless Steel for Wetted Parts: All parts that come into contact with the transferred fluid (lobes, pump body, inlet/outlet ports) are made of 316/316L stainless steel.

- Surface Finish Meeting Ra ≤ 0.8μm: The inner surface of the pump chamber is polished to a roughness of Ra ≤ 0.8μm. This ultra-smooth surface not only reduces fluid friction (protecting shear-sensitive media like yogurt or biological slurries) but also prevents residues from adhering—making cleaning faster and more thorough.

About BONVE

Top quality lobe pump manufacturer since 2001 | Pump solution supplier for high viscosity liquid

- 25+ Years of Expertise: Reliable technology and experience since 2001.

- Full-chain In-house Control: Independent design, R&D, and production with traceable quality.

- High-precision CNC Manufacturing: Guarantees product accuracy and consistency.

- Flexible Customization (OEM/ODM): Low MOQ options and competitive factory-direct pricing.

- Efficient Capacity & Delivery: 350+ units monthly output; 7-day lead time for standard pumps.

- Professional Seal Solutions: Expertly customized sealing systems—matched to media and conditions—for leak-free and safe operation.

- Full-cycle Technical Support: Senior sales engineers provide end-to-end guidance from design to project completion.

What are the critical advantaged of Bonve lobe pump to transfer high viscous products?

Special bearings tructure

The inner gear box is designed with six separately arranged bearing structures (each shaft has three bearings), so that the shaft is stressed at three points in one, and then processed by high-precision equipment, so that the rotor and the pump body have no friction coefficient.

This design greatly increases the concentricity of the pump operation, enhance the bearing capacity of the shaft and make the structure more stable, thereby increasing the service life of the shaft, the mechanical seal and complete pump.

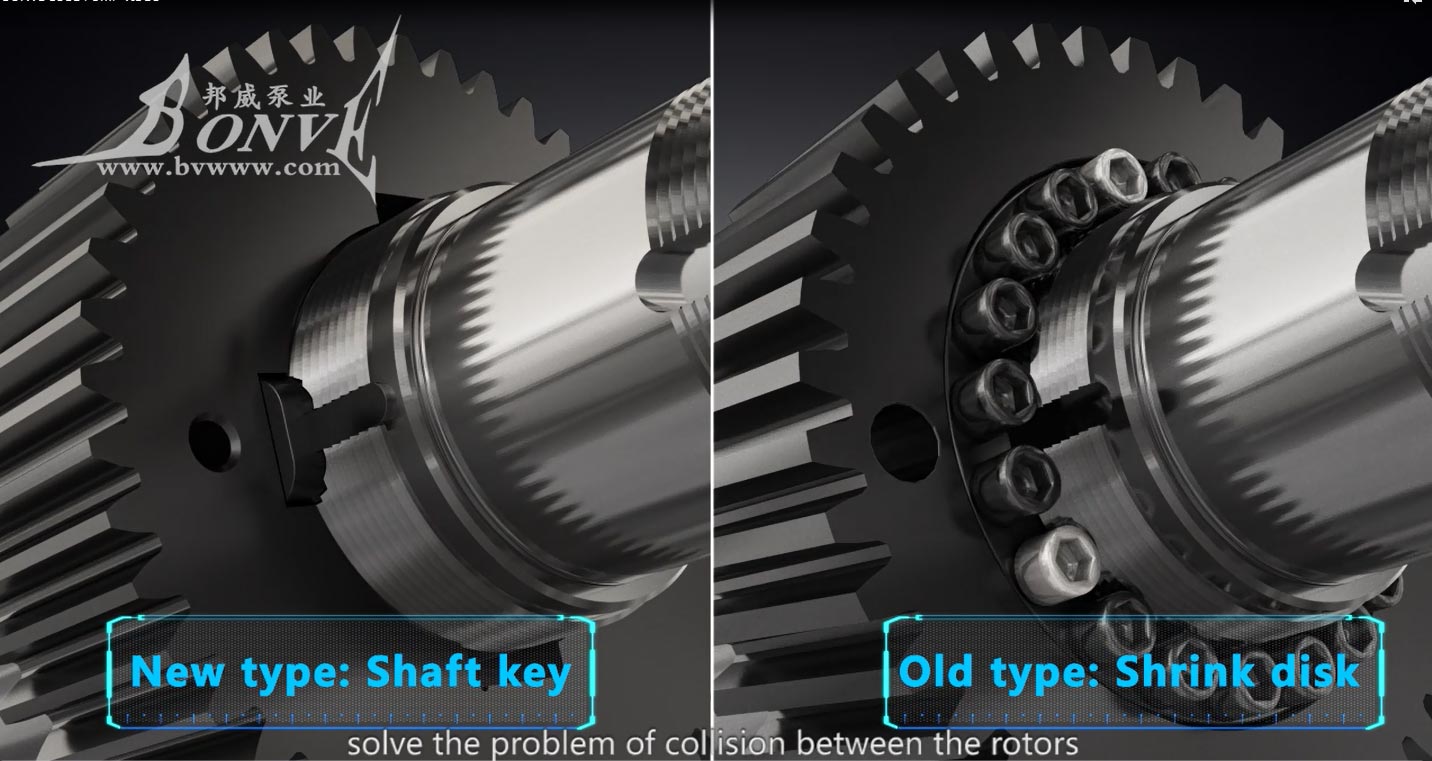

Special shaft fixing way

The combination of synchronous gear and shaft adopts key structure design to replace of shrink disk, so as to avoid the phenomenon of gear slipping or rotor collision when the pump is under high pressure, high viscousity and instant start.

More details about Beverage Flavor Syrups Lobe Pump, pls click the below pump picture.