Cleaning of the installations is necessary and mandatory on completing any manufacturing process in the food industry. The use of an installation which is NOT cleaned can cause contamination of the products. The cleaning cycles as well as the chemical products and procedures used will vary depending on the product and the manufacturing process.

The pump can be cleaned easily and thoroughly in one of two ways:

• Without disassembling it, for ex., using steam or water, referred to as CIP (Cleaning in Place).

• By simply disassembling the pump cover, the lobes, the pump cover and the mechanical seal.

In most installations it is important to ensure the maximum recovery of pumped product residues from the production line at the end of each production run. Where this is a requirement, consideration should be given to mounting Rotary lobe pumps with ports in the vertical direction to maximize drainability. This will minimize any product loss, ease the cleaning of the system and reduce the requirement to dispose of or recycle the wash from the initial cleaning cycles. By maximizing the recovery of product from the system both the efficiency of the production and cleaning processes will be increased.

Rotary lobe pumps are rarely used as the supply pump for CIP fluids. Centrifugal pumps are generally used during CIP for each phase of the cleaning cycle. For the majority of CIP cycles it is recommended that a differential pressure of 2 to 3 bar is created across the pump to promote efficient cleaning, whilst it is rotating at it’s normal operating speed. In many cases a valve is employed in the discharge line of the system to create the differential pressure across the pump and a by-pass loop installed around the pump to divert any excess of CIP liquid that the pump is unable to transfer. The valve (s) setting may be fluctuated during the CIP cycle to promote pressure/flow variations that may enhance the cleaning process.

During the CIP cycle there must always be sufficient flow of cleaning fluid being delivered by the CIP pump to make sure that the centrifugal or rotary lobe pump is neither starved of liquid at it’s inlet due to its own flow capability, or overpressurised at it’s inlet due to its tendency to act as a restriction if it is unable to transfer the full flow of the fluid being delivered to it.

Generally the most effective cleaning processes incorporate five stages:

1. An initial rinse of clean, cold water.

2. Rinsing with an alkaline detergent.

3. Intermediate rinse with cold water.

4. Rinsing with an acidic disinfectant.

5. Final rinse with clean cold water.

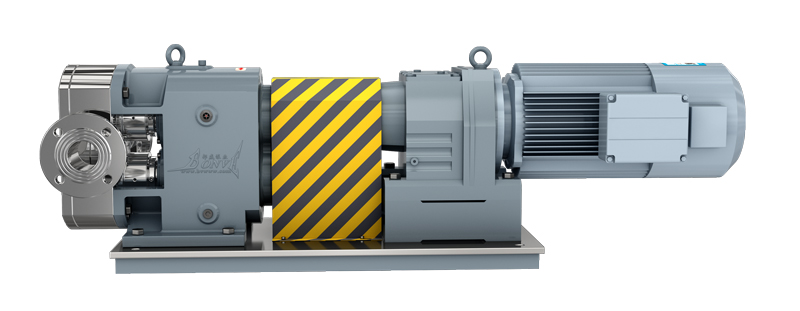

Bonve Lobe pumps are engineered to perfection with innovative design and stringent quality control to give you trouble free service. If have any pump demand to transfer high viscous, high density and corrosive liquids, Bonve will be your right supplier. Pls click the pump photo to learn more.