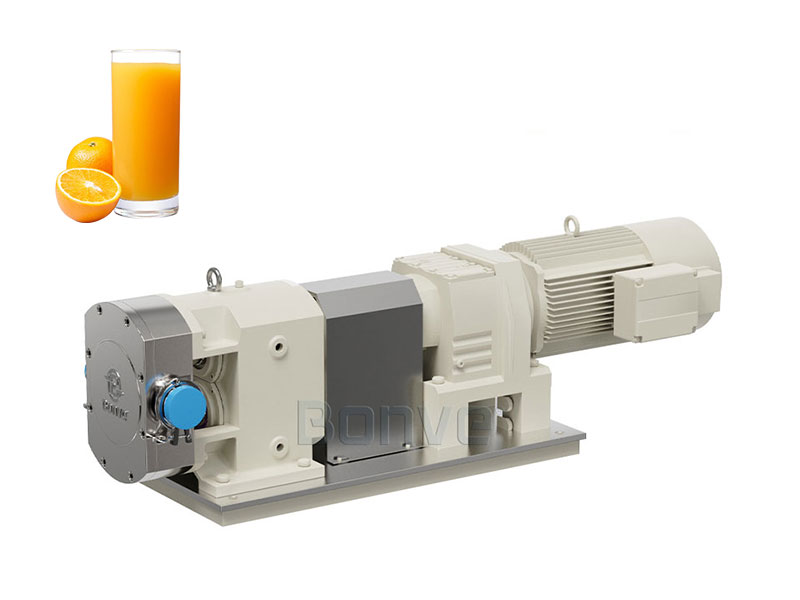

Food Grade SS316 Rotary Lobe Pumps for Concentrated Juice Transfer

Bonve rotary lobe pump isn't just a pump, it's a commitment to quality.

Engineered specifically for delicate dairy products, Bonve rotary lobe pump ensures your concentrated juice's signature texture, viscosity, and creamy mouthfeel are maintained from mixing tank to filling line.

Say goodbye to product degradation and hello to unmatched operational efficiency.

The Challenge: Why Standard Pumps Fail Concentrates

Concentrated juices are the lifeblood of your operation, but they are notoriously demanding. Their high viscosity, abrasive solids, and sensitive nature can wreak havoc on standard equipment.

Shear Damage: Centrifugal pumps destroy delicate cell structures, leading to flavor loss, color degradation, and separation.

Inefficiency & Cavitation: High viscosity starves inefficient pumps, causing cavitation, inconsistent flow, and high energy waste.

Product Trapping & Contamination: Complex internal geometries harbor product and bacteria, making cleaning a nightmare and risking entire batches.

Excessive Downtime: Frequent cleaning, maintenance, and breakdowns halt your production line, costing you time and money.

Bonve Concentrated Juice Pumping Solution

Bonve rotary lobe pump addresses this core challenge with its innovative low-speed, high-volume design. Unlike centrifugal pumps, our rotary lobe technology moves product using two synchronized, non-contacting lobes. This creates a gentle, positive displacement action that lifts the concentrated juice rather than tearing it apart, guaranteeing that what you produce is exactly what your customer enjoys.

Bonve Rotary Lobe Pump Advantage

Designed specifically for thick, particle-laden fluids, Bonve Rotary Lobe Pump excels in concentrated juice handling with these innovations:

1. Gentle-Flow Rotor DesignUnlike traditional gears, our synchronized, non-meshing rotors "lift" the product through the pump chamber. This creates a smooth, non-pulsating, low-shear flow that protects the most sensitive concentrates, from delicate berry purees to thick tomato paste.

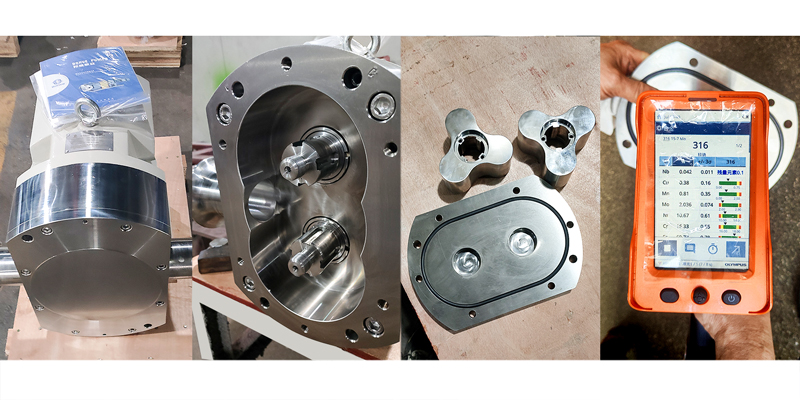

2. Unmatched Hygienic Construction

Constructed from premium 316L stainless steel with electropolished finishes (Ra < 0.6 µm). All product-contact surfaces comply with FDA and CE regulations. Tri-Clamp connections provide a seamless, leak-free integration into your sanitary process line.

3. Built for the Toughest Environments

The sealed, cartridge-style mechanical seal is designed for longevity and is available in various materials to handle a wide range of temperatures and pH levels. The robust drive train is engineered for high torque demands, ensuring reliability under continuous heavy load.

4. Smart & Easy Maintenance

The front-cover, quick-release design allows for rotor inspection and seal replacement in minutes without disconnecting the pump from the pipeline. This modularity drastically reduces Mean Time To Repair

Why Choose Bonve Concentrated Juice Lobe Pump ?

1. Product Integrity Guarantee: Bonve primary design goal is to protect your product's quality.

The low-Speed, low-shear operation ensures your concentrated juice's sensory properties remain intact.

2. Proven Expertise: Over 15 years of experience in the dairy and food industry.

3. Custom Solutions: Pumps can be customized to fit your exact production line layout.

FAQ Section

-

Q: How does the low-shear design work?

A: The low-shear operation is achieved through a combination of large pumping chambers, optimized rotor profiles, and slower operating speeds compared to centrifugal pumps. This minimizes the mechanical agitation and shear forces that can damage concentrated juice's protein structure. -

Q: Are your seals compatible with hot cleaning and caustic solutions?

A: Absolutely. We offer a range of FDA-compliant seal materials (like FKM/Viton) specifically chosen to withstand high temperatures and aggressive CIP chemicals. -

Q: Do you offer custom configurations?

-

A: Yes. We can customize port sizes, surface finishes, and motor specifications to meet your exact plant layout and process requirements.

About Bonve Rotary Lobe Pump

Bonve offers the broadest range of its Rotary Lobe Pumps for food industry. As an excellent pump manufacturer, our hard technical barriers have become a powerful help for our Bonve pumps reform and innovation. So far, Bonve pumps have developed to the fourth generation and are mature.

Interchangeable

· Interchangeable rotors, one pump multi-purpose.

· Targeted seal for specific application, ensure zero leakage.

Easy maintenance

· Compact structure, easy assembling and disassembling

· Maintenance in place, easy cleaning, CIPable and SIPable.

· Few wearing parts, low maintenance.

Long life

· All main parts proceed by CNC, high precision fabrication.

· No contact between the rotors, rotors and pump chamber.

· Six bearings with separate arrangement, high balance.

· Adjustable seal ring extends the shaft life.

· Axis key synchronous adjustment, no rotor collision problem.

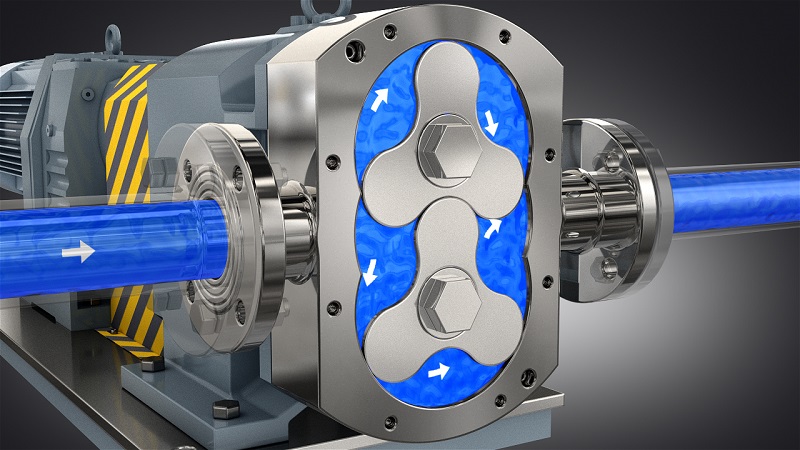

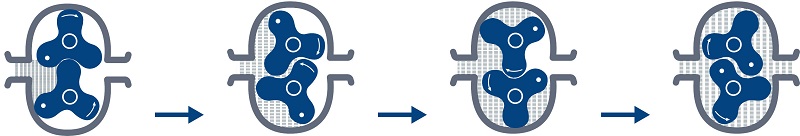

Working Principle

Bonve lobe pumps basically consist of two lobe rotors, which rotate synchronously driven by a pair of synchronous gears in the gearbox. The rotors are driven by the main shaft and sub-shaft to rotate in a synchronous reverse direction, which changes the pump capacity, builds up high vacuum and discharge pressure, thus an efficient pumping is formed. Gap is kept between the rotors and between the pump casing, no friction, long life, no damage, no physical and chemical reaction to the pumped products.

Bi-wing rotor diagram

Tri-lobe rotors diagram

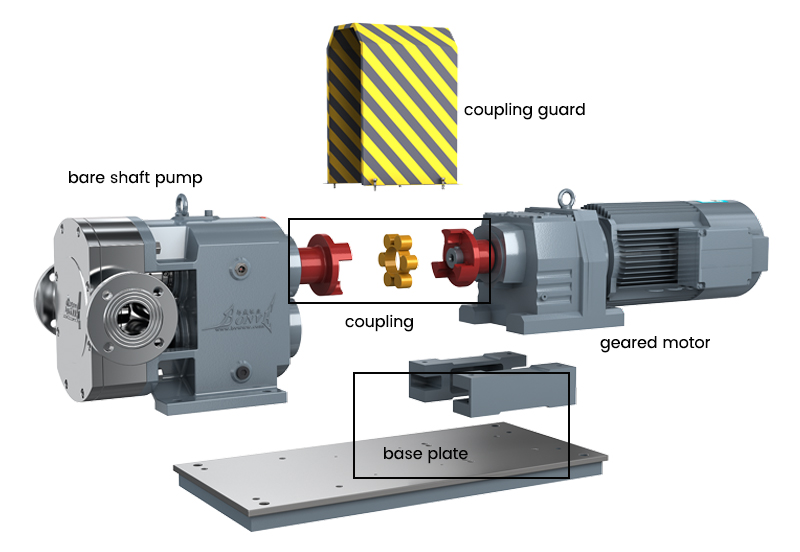

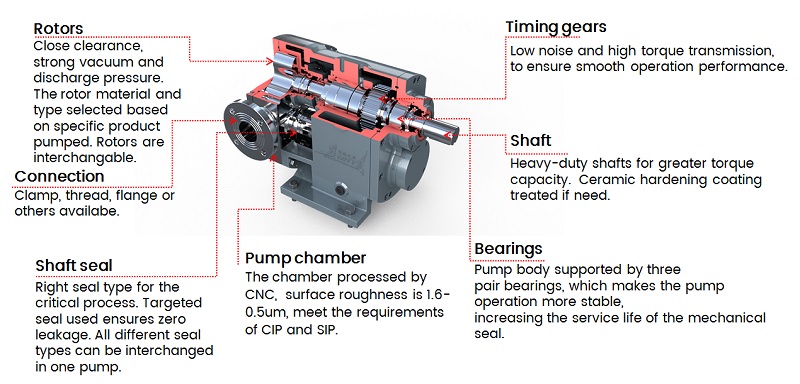

Main Parts of the Complete Pump

Bonve complete pumps are usually composed of bare shaft pump, coupling and its guard, geared motor and baseplae. With your order, bare shaft pump or complete pump is supplied.

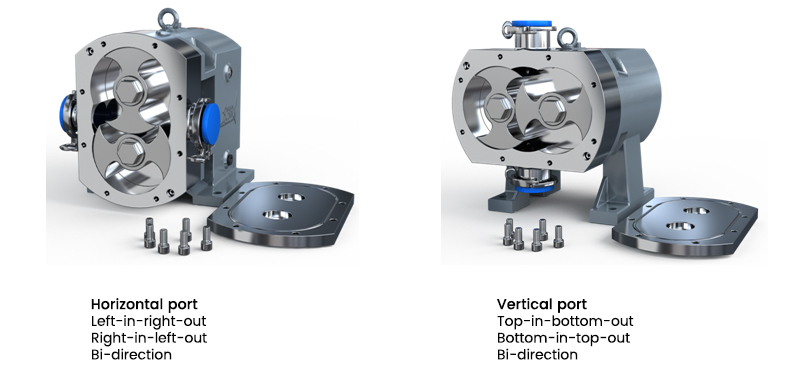

Bare Shaft Pump Structure

Based on the port direction, we have the pump with horizontal port and vertical port to meet your site installation.

Structure Details

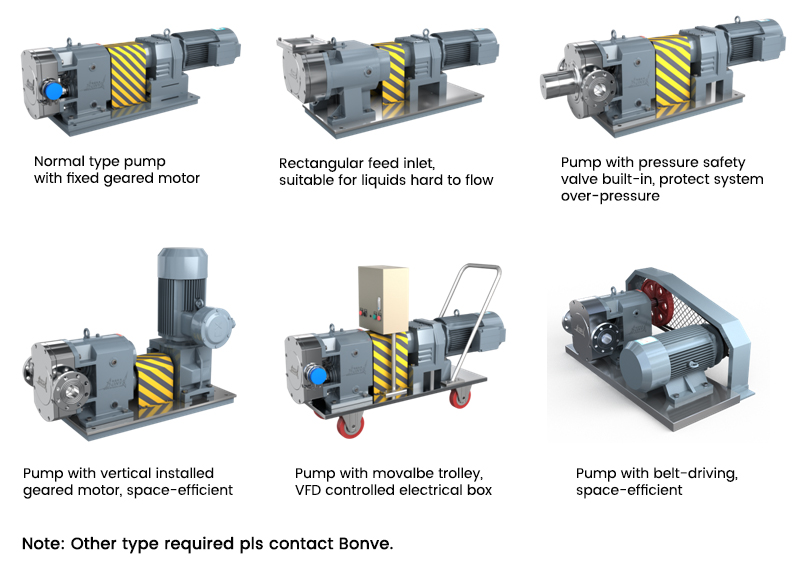

Complete Pump Types

Technical Parameters

|

Model |

Displace -ment |

RPM |

Flow |

Dis. Pre. |

Power |

Vacuum |

Port size |

Max viscosity |

|

|

(L/r) |

(r/min) |

(m³/h) |

(Mpa) |

(kW) |

(Mpa) |

(mm) |

(cp) |

|

25BV12-05 |

0.06 |

10-1000 |

0-0.5 |

0-1.2 |

0.37-1.1 |

-0.080 |

25 |

1,500,000 |

|

40BV12-2 |

0.15 |

10-1000 |

0-2 |

0-1.2 |

0.75-2.2 |

-0.080 |

40 |

1,500,000 |

|

50BV12-5 |

0.32 |

10-800 |

0-5 |

0-1.2 |

1.5-4 |

-0.085 |

50 |

1,500,000 |

|

65BV12-10 |

0.65 |

10-600 |

0-10 |

0-1.2 |

2.2-7.5 |

-0.085 |

65 |

1,500,000 |

|

80BV12-20 |

1.74 |

10-500 |

0-20 |

0-1.2 |

4-15 |

-0.095 |

80 |

1,500,000 |

|

90BV12-30 |

2.60 |

10-500 |

0-30 |

0-1.2 |

5.5-22 |

-0.095 |

100 |

1,500,000 |

|

100BV12-40 |

3.65 |

10-500 |

0-40 |

0-1.2 |

7.5-30 |

-0.095 |

100 |

1,500,000 |

|

125BV12-50 |

4.60 |

10-500 |

0-50 |

0-1.2 |

7.5-37 |

-0.095 |

125 |

1,500,000 |

|

140BV12-70 |

6.10 |

10-500 |

0-70 |

0-1.2 |

11-45 |

-0.095 |

150 |

1,500,000 |

|

150BV12-80 |

7.63 |

10-500 |

0-80 |

0-1.2 |

11-55 |

-0.095 |

150 |

1,500,000 |

|

200BV12-120 |

11.56 |

10-400 |

0-120 |

0-1.2 |

15-75 |

-0.095 |

200 |

1,500,000 |

|

250BV12-150 |

14.22 |

10-400 |

0-150 |

0-1.2 |

18.5-90 |

-0.095 |

250 |

1,500,000 |

|

300BV12-200 |

20.80 |

10-300 |

0-200 |

0-1.2 |

22-110 |

-0.095 |

300 |

1,500,000 |

|

350BV12-300 |

32.60 |

10-250 |

0-300 |

0-1.2 |

45-160 |

-0.095 |

350 |

1,500,000 |

|

400BV12-400 |

50.40 |

10-250 |

0-400 |

0-1.2 |

55-200 |

-0.095 |

400 |

1,500,000 |

Note:

1. Tested medium: water.

2. Speed, flow rate, electrical power and pressure will be varified according to different product properties.

Selection Guidelines

|

Your Industry |

|

||

|

About pump medium |

Name: |

||

|

Density (g/m³): |

|||

|

Viscosity (mPa.s): |

|||

|

Temperature (℃): |

|||

|

PH value: |

|||

|

Solid content (%): |

|||

|

Solid size (mm): |

|||

|

Suction side |

Pressure: Positive ( ) bar; Negtive ( ) bar |

How high (m): |

|

|

Suction pipe length (m): |

Diameter (mm): |

||

|

Bends (Pcs): |

T-piece (Pcs): |

Valves (Pcs): |

|

|

Discharge side |

Pressure (Mpa): |

||

|

Vertical delivery pipe length (m): Total delivery pipe length (m): |

Diameter (mm): |

||

|

Bends (Pcs): |

T-piece (Pcs): |

Valves (Pcs): |

|

|

Required flow rate (L/H) |

Operating flow: |

Max. flow: |

|

|

Pump material required |

SS304 ( ) SS316 ( ) SS316L ( ) Duplex stainless steel ( ) |

||

|

Motor required |

Phase: Single ( ) Three ( ) |

Voltage (V): |

Frequency (Hz): |

|

IP grade: |

Energy efficiency: |

Anti-explosive: |

|

|

Installation type |

Fixed ( ) |

Movable ( ) |

Fixed with adjusting feet ( ) |

|

Others |

|

||

About Us

BONVE is a Chinese leading manufacturer in ROTARY LOBE PUMPS and HOMOGENIZER MIXERS. Providing its customers with customized pumping and mixing solutions and solving their problems during the production.

Bonve pumps and mixers are widely used in food, dairy, beverages, chemical, pulp&paper, soaps&detergents, pharmaceuticals, pesticide, coatings etc. By 2024, Bonve served 8,000+ customers in various industries and 100,000+ pumps running in the worldwide.

Time and again companies specify Bonve pumps as the "standard" equipment for their manufacturing processed. We are looking forward to be partner with you.

Contact Us

We welcome you to contact us for a pump solution if have any demand.

Contact person: Cathy Bao

Tel: +86-574-87769810 Fax: +86-574-62962898

Mobile/Whatsapp/Wechat: +86 13616639068

Email: Cathy@bonvepumps.com