Bonve pumps are to be found in numerous processes for transfer purpose, where their reliable sealing, low maintenance, No-stop working, long life characteristics are ideally suited to the production of Paper, Package and Paperboard. We select the pump according to your characteristics of medium and condition of the technological requirements, bring you the best pump for your critical process, satisfied by you and your customers.

Typical mediums to be transferred by Bonve pump

Cooked Starch, Coating Pigments, Anti-foaming agents, CMC, Polymers, Starch Slurry, Specialty Chemicals, Emulsions, Resins, Retention Aids, Sizing agent, Flocculating agent, Dry/wet strength agent, Softening agent/softener

Who we worked with?

Field operating photos

Bonve pumps advantages?

Displacement: positive displacement, Displacement is proportional to the speed. Max. Capacity is upto 300m3/h.

Discharge pressure: upto 1.2Mpa.

Suction capacity: Movable pumps can be used to pump canned medium, with intake vacuum of 0.08 Mpa.

Work efficiency: upto 90%

Special mediums to handle: high viscosity upto 1.5million cps, high solid mediums upto 60%, sensitive mediums.

Reversible running allowed: Forward suction, reversal flushing can be realized with pump's symmetric structure, reversible transportation direction.

Dry running: with Bonve's special design on mechanical seal, dry running can be realized.

Maintenance: Compact structure, little space occupation, no need to move pipe systems when maintain.

Wear-resisting: all the contact parts are made of stainless steel. Nearly no wearing parts.

Low shearing: Low working speed, gap is kept between the rotors and between the rotor and the pump body, no friction,long life.

Replacement: take replace of screw pumps.

Low cost: high working efficiency, low consumption, environmental friendly, low maintenance, long life.

What pump Bonve supplied?

Bonve offers the broadest range of its rotary lobe pumps for paper industry. As a recognised market leader in pumping technology Bonve has been at the forefront of supplying rotary lobe pumps to the Paper&package industry for over 18 years.

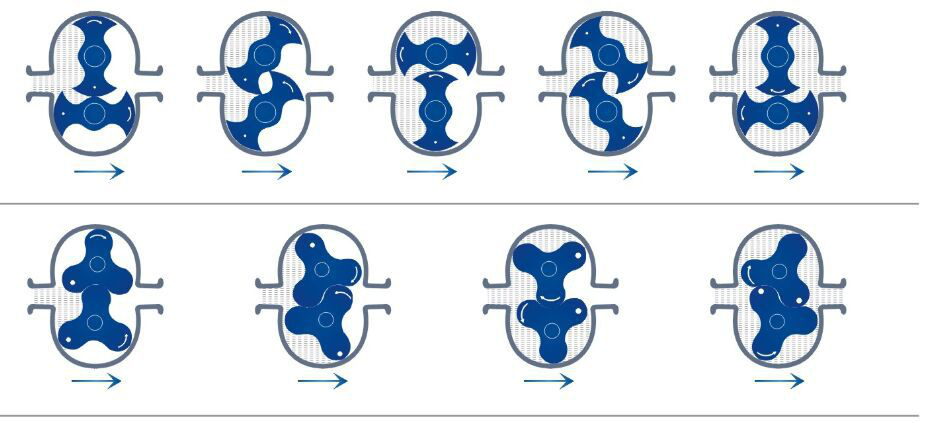

How pump works?

The even rotation of the rotor pair creates a vacuum on the priming side of the pump, which can be defined by the direction of rotation of the drive. This vacuum draws the liquid into the pump chamber. With further rotation, the pumped medium is conveyed past the pump wall into the pressure area. Up to six chamber charges are displaced with each drive rotation– depending on the rotor type. When the rotor is at a standstill, the pump seals off almost completely.

Pump technical parameters

Model

Displace

-ment

(L/r)

Rotation

speed

(r/min)

Flow

rate

(M³/h)

Dis.

Pre.

(Mpa)

Electrical

power

(Kw)

Suc.

Pre.

(Mpa)

Dia. of inlet and outlet (mm)

25BV6 /12-2

0.15

20-600

2

0.1-1.2

1.1-2.2

-0.095

25

40BV6 /12-5

0.32

20-550

5

0.1-1.2

1.5-4

-0.095

40

50BV6 /12-10

0.65

20-550

10

0.1-1.2

2.2-7.5

-0.095

50

65BV6 /12-20

1.74

20-550

20

0.1-1.2

4-15

-0.095

65

80BV6 /12-30

2.48

20-550

30

0.1-1.2

5.5-22

-0.095

80

80BV6 /12-40

3.65

20-550

40

0.1-1.2

7.5-30

-0.095

100

125BV6 /12-50

4.60

20-550

50

0.1-1.2

11-45

-0.095

125

125BV6 /12-70

6.10

20-550

70

0.1-1.2

15-55

-0.095

125

125BV6 /12-80

7.63

20-550

80

0.1-1.2

18.5-75

-0.095

125

150BV6 /12-120

11.56

20-420

120

0.1-1.2

22-90

-0.095

150

150BV6 /12-150

14.22

20-420

150

0.1-1.2

37-110

-0.095

150

200BV6 /12-200

18.10

20-420

200

0.1-1.2

45-132

-0.095

200

250BV6 /12-250

22.92

20-420

250

0.1-1.2

55-160

-0.095

250

300BV6 /12-300

32.00

20-420

300

0.1-1.2

75-200

-0.095

300

Selection guideline

|

Liquid information |

|

Your industry: __________ Liquid name:___________ |

|

Features: Sanitary[ ] Corrosive[ ] Poisonous[ ] |

|

Viscosity:_______cp Density:_______ Temperature:_____℃ PH value:________ |

|

Solid content:_______ Max. size of particle:_______ |

|

Using condition |

|

Capacity: Max. required__________ L/H Working required__________ L/H |

|

Discharge pressure: Max. required__________Mpa Working required__________ Mpa |

|

Suction pressure: Max. required__________Mpa Working required____________ Mpa |

|

Delivery head required:____________ Vacuum:________ Mpa |

|

Heating jacket required: Yes[ ] No.[ ] Heating temp.:_____℃ |

|

Liquid inlet/outlet direction: Horizontal[ ] vertical[ ] |

|

Pipe size: Inlet___________ Outlet____________ |

|

Connection type required: Flange[ ] Thread[ ] Clamp[ ] |

|

Installation type: Fixed [ ] Movable[ ] |

|

Operating status: Continuous[ ] Interruption[ ] |

|

Liquid contact material: SS304[ ] 316[ ] 316L[ ] Others________ |

|

Special request_____________________________________ |

|

Order qty. |

More pump details pls contact cathy@bonvepump.com for a pump solution.