Bonve Lobe pumps are widely used for cosmetics and personal cares to transfer of products such as serums, creams, lotions, shampoo, toothpaste,particle-based products. Bonve positive displacement pumps are ideal for handling delicate and viscous materials, and they offer a gentle pumping action that minimizes shear stress on the product.

Bonve Lobe pumps consist of two rotating lobes that create a vacuum, which draws the liquid through the pump and into the discharge port. The lobe pumps are designed to maintain a constant flow rate regardless of the pressure or viscosity of the product being pumped.

Some benefits of using Bonve lobe pumps will include:

- Gentle handling: The gentle pumping action of lobe pumps ensures that even delicate and sensitive products are handled with care.

- High efficiency: Lobe pumps are incredibly efficient, with a high volume flow rate and low power consumption.

- High accuracy and precision: Lobe pumps are designed to deliver exact flow rates, which is critical for cosmetic products that need precise dosing.

- Easy maintenance: Lobe pumps require minimal maintenance, and they have fewer parts, making them easy to disassemble and clean.

Bonve Lobe pumps are an excellent choice for cosmetic applications due to their ability to handle delicate and viscous materials, maintain a constant flow rate, and offer easy maintenance.

Typical Applications

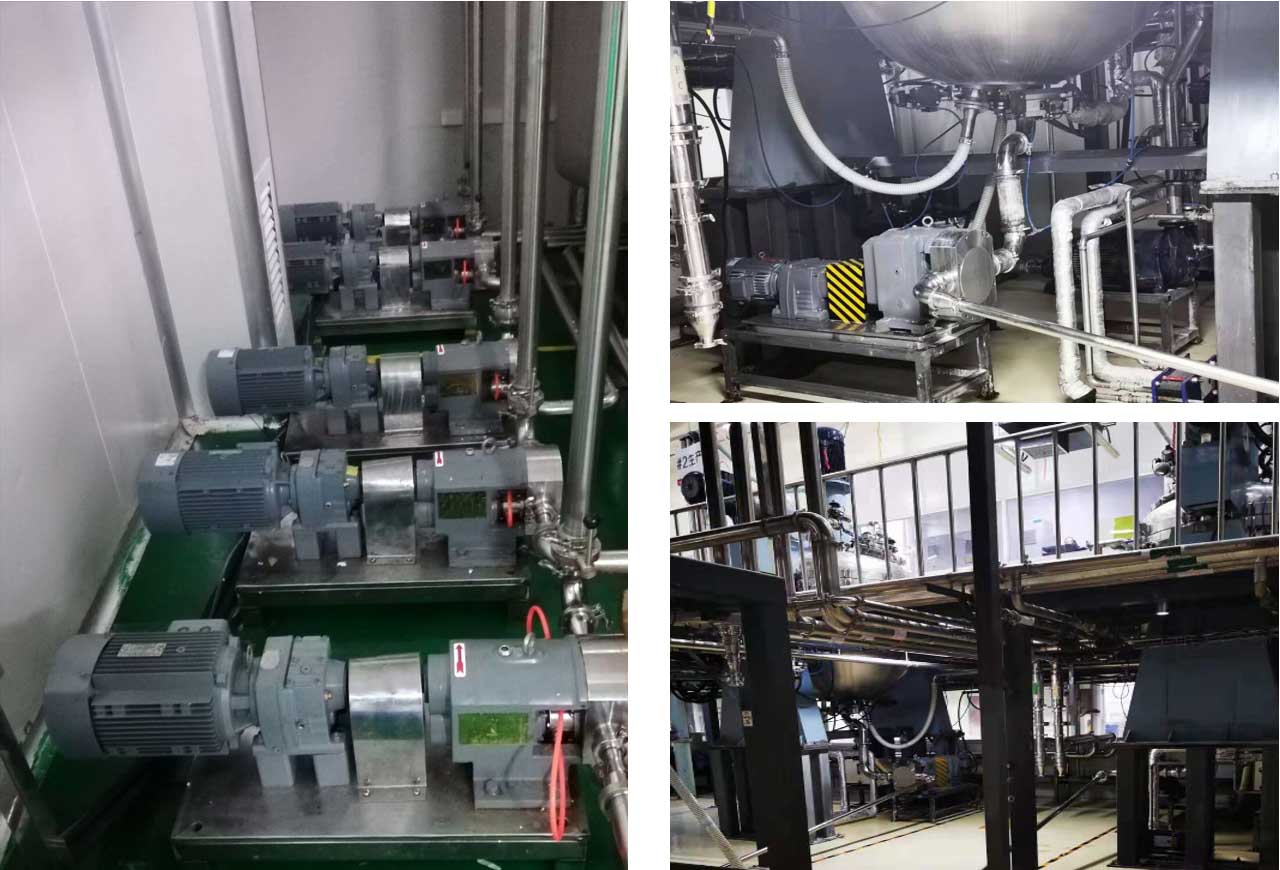

- Transferring emulsions (moisturizers, foundations) between mixing tanks and filling lines

- Dosing serums, essences, or oils into small-pack containers

- Handling particle-based products (facial scrubs, body polishes)

- Recirculating creams to maintain temperature and consistency during production

- Transferring high-viscosity waxes for lip balms or solid perfumes

- Built to meet the cosmetics industry’s strict standards for hygiene, performance, and product protection, BONVE lobe pump is the reliable choice for brands prioritizing quality, efficiency, and compliance.

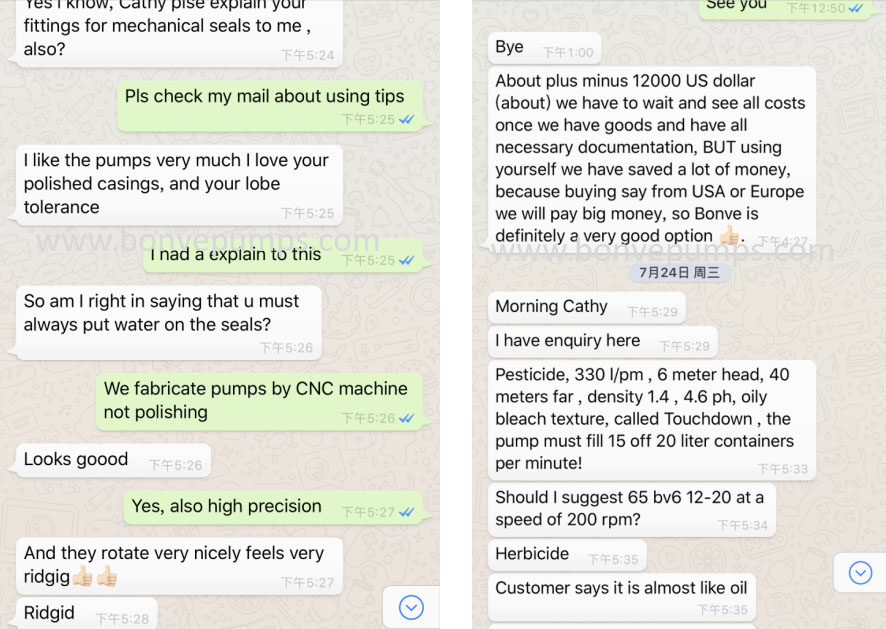

How customers' comments on Bonve Lobe pump

Comment on the pumps surface finish

We worked with an pump re-seller and they are very happy with Bonve lobe pump surface smooth finish and price.

If your team is dealing with similar pain points—whether it's subpar materials, inconsistent finishes, or non-compliant equipment—let's connect. We're here to deliver the same peace of mind and performance to your operations.

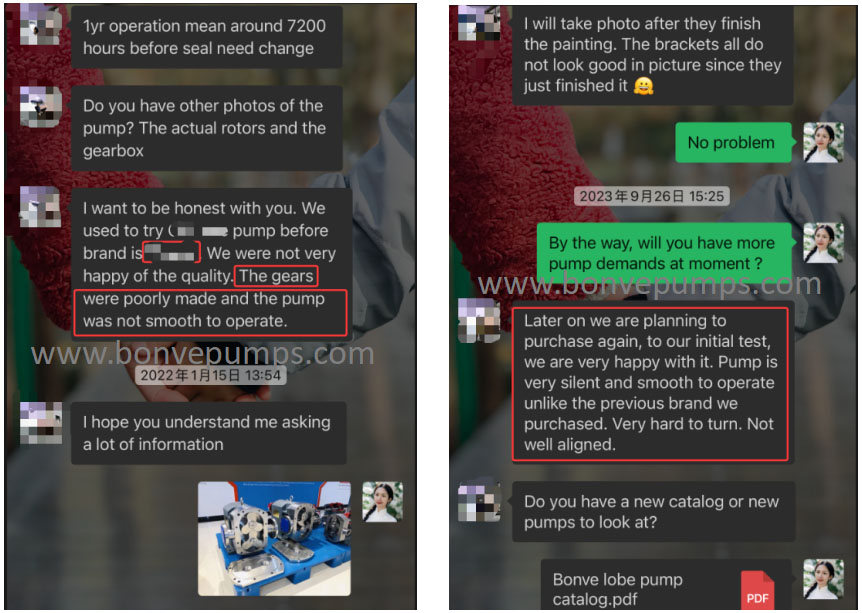

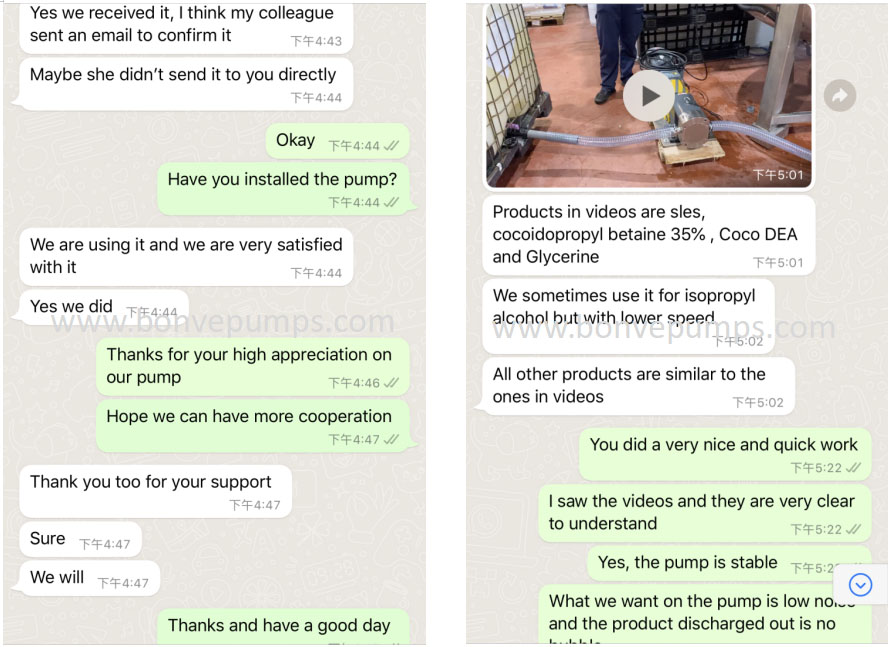

Feedback on Bonve lobe pump inner structure and running

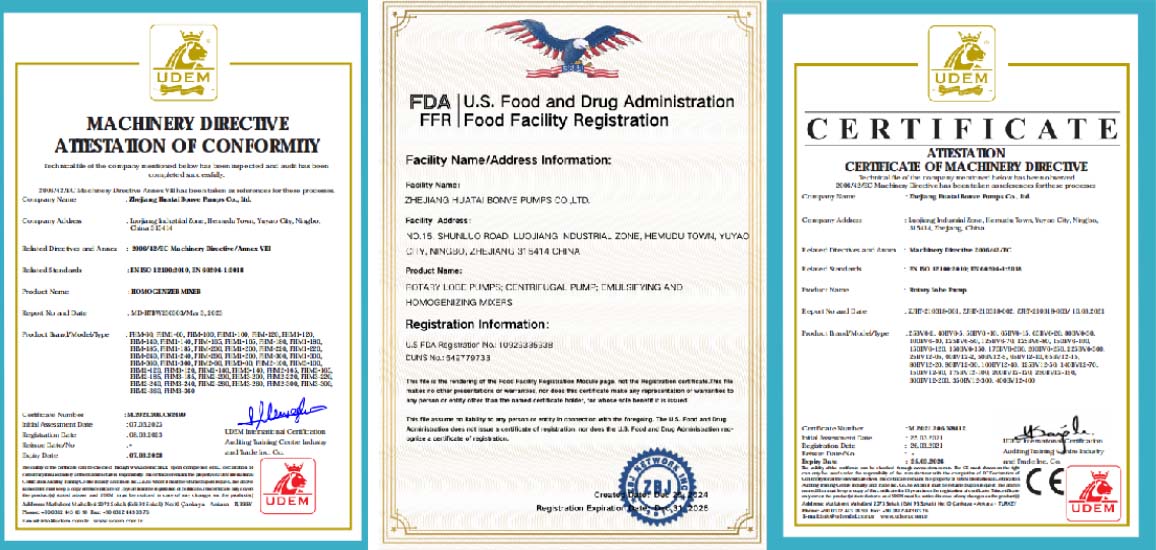

Certificate

Bonve ISO9001, ISO14001, ISO45001 certificates ensure quality consistency, compliance reliability, environmental responsibility, and operational efficiency, delivering trustworthy and sustainable partnerships for our clients.

With CE and FDA certificates, Bonve pumps are globally recognized. These certificates open doors to major markets, and they're a testament to our pumps excellence for you.

About Bonve Rotary Lobe Pump

Bonve Rotary Lobe Pump is A Reliable Choice for Fluid Transfer Across Industries.Whether it’s highly corrosive liquids in the food industry, viscous materials with solid particles in the cehmical sector, or fluids with diverse properties in other fields—Bonve Rotary Lobe Pumps handle them all with ease. Specifically designed for over 3,000 types of fluids, they enable efficient transfer of media with varying viscosities and solid contents, making them widely suitable for needs across different industries.

What’s more, Bonve remains committed to technological innovation. Today, its rotary lobe pumps have been upgraded to the 4th generation. The new-generation products feature further optimized core performance, which significantly extends the pump’s service life—helping you reduce equipment replacement costs and ensure stable production operations.

Interchangeable

· Interchangeable rotors, one pump multi-purpose.

· Targeted seal for specific application, ensure zero leakage.

Easy maintenance

· Compact structure, easy assembling and disassembling

· Maintenance in place, easy cleaning, CIPable and SIPable.

· Few wearing parts, low maintenance.

Long life

· All main parts proceed by CNC, high precision fabrication.

· No contact between the rotors, rotors and pump chamber.

· Six bearings with separate arrangement, high balance.

· Adjustable seal ring extends the shaft life.

· Axis key synchronous adjustment, no rotor collision problem.

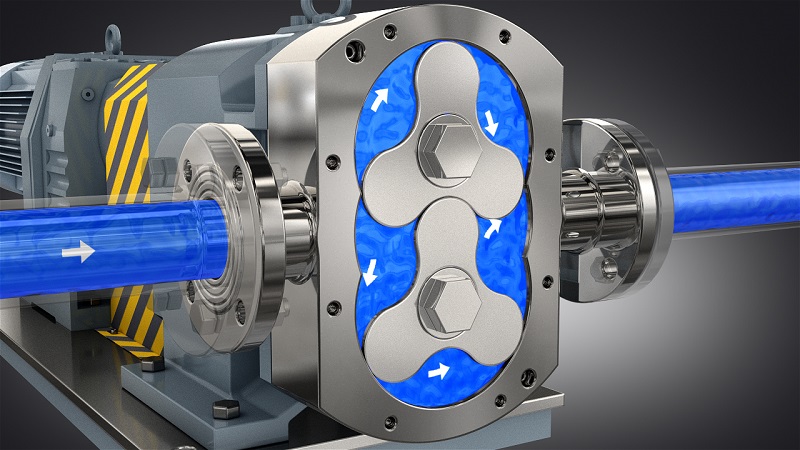

Working Principle

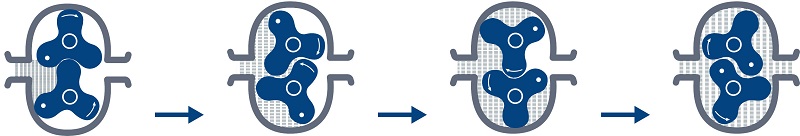

Bonve lobe pumps basically consist of two lobe rotors, which rotate synchronously driven by a pair of synchronous gears in the gearbox. The rotors are driven by the main shaft and sub-shaft to rotate in a synchronous reverse direction, which changes the pump capacity, builds up high vacuum and discharge pressure, thus an efficient pumping is formed. Gap is kept between the rotors and between the pump casing, no friction, long life, no damage, no physical and chemical reaction to the pumped products.

Bi-wing rotor diagram

Tri-lobe rotors diagram

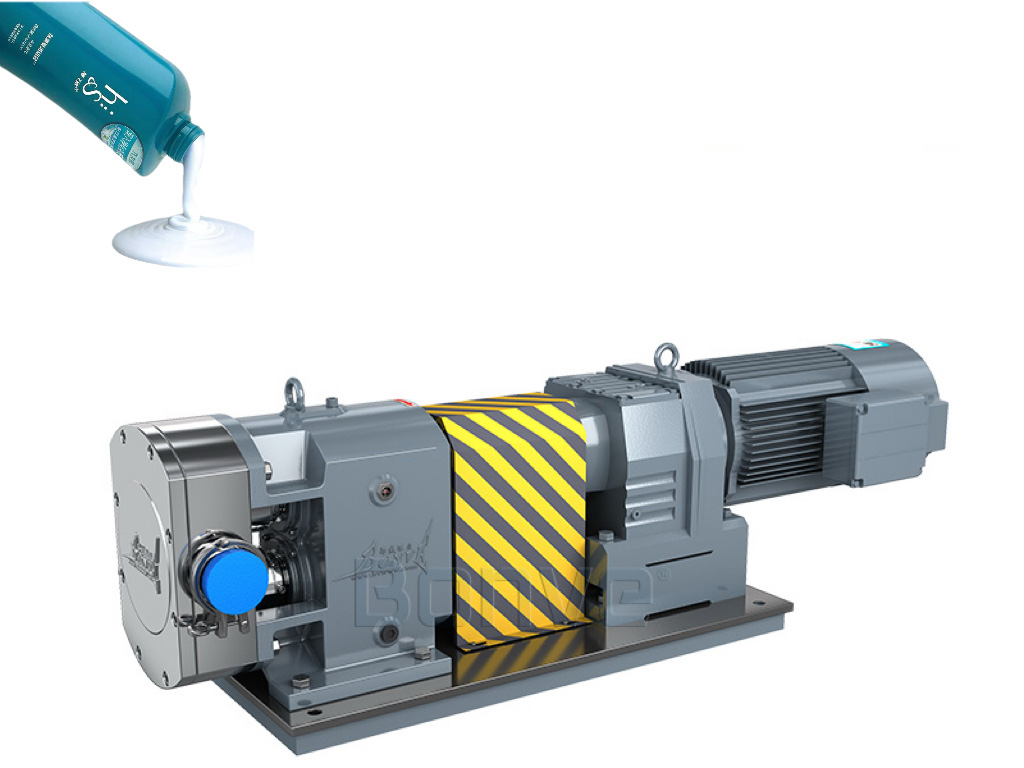

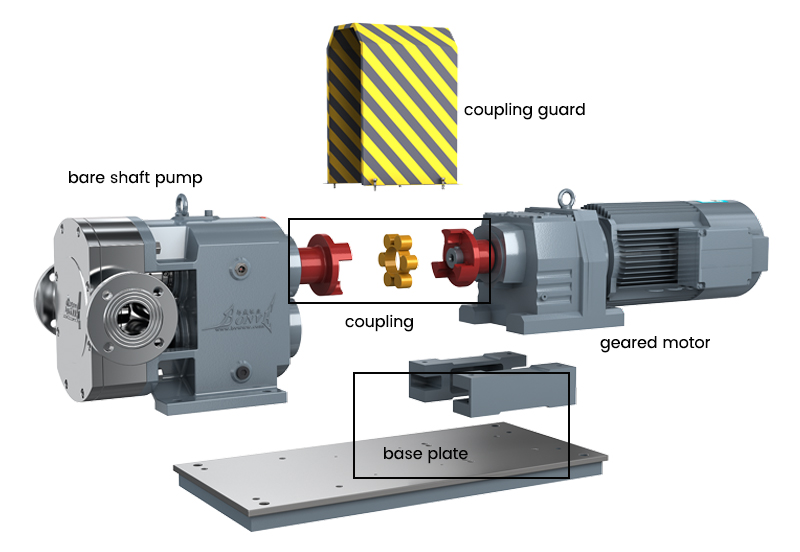

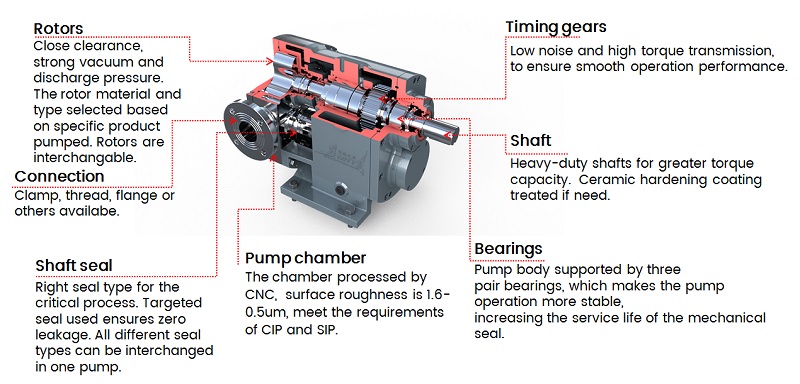

Main Parts of the Complete Pump

Bonve complete pumps are usually composed of bare shaft pump, coupling and its guard, geared motor and baseplae. With your order, bare shaft pump or complete pump is supplied.

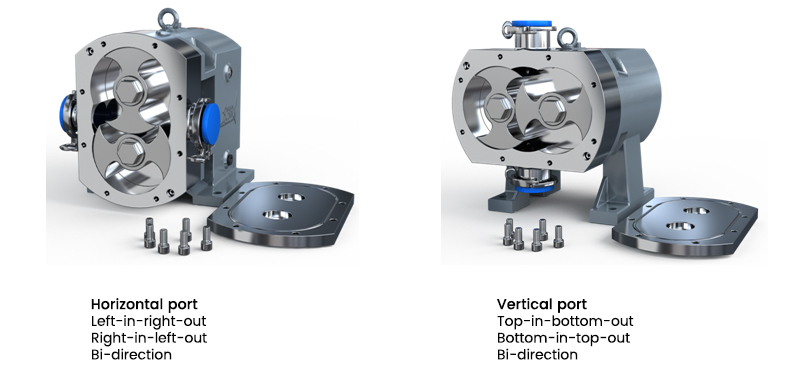

Bare Shaft Pump Structure

Based on the port direction, we have the pump with horizontal port and vertical port to meet your site installation.

Structure Details

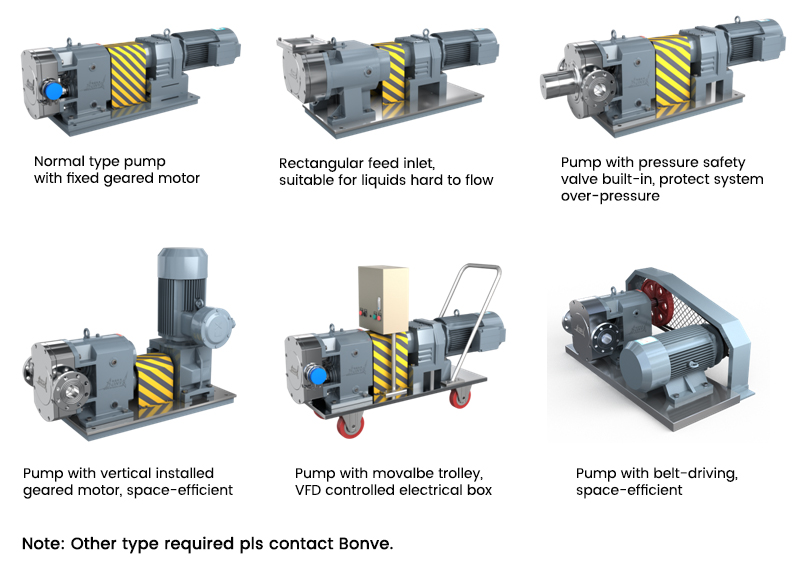

Complete Pump Types

Technical Parameters

|

Model |

Displace -ment |

RPM |

Flow |

Dis. Pre. |

Power |

Vacuum |

Port size |

Max viscosity |

|

|

(L/r) |

(r/min) |

(m³/h) |

(Mpa) |

(kW) |

(Mpa) |

(mm) |

(cp) |

|

25BV12-05 |

0.06 |

10-1000 |

0-0.5 |

0-1.2 |

0.37-1.1 |

-0.080 |

25 |

1,500,000 |

|

40BV12-2 |

0.15 |

10-1000 |

0-2 |

0-1.2 |

0.75-2.2 |

-0.080 |

40 |

1,500,000 |

|

50BV12-5 |

0.32 |

10-800 |

0-5 |

0-1.2 |

1.5-4 |

-0.085 |

50 |

1,500,000 |

|

65BV12-10 |

0.65 |

10-600 |

0-10 |

0-1.2 |

2.2-7.5 |

-0.085 |

65 |

1,500,000 |

|

80BV12-20 |

1.74 |

10-500 |

0-20 |

0-1.2 |

4-15 |

-0.095 |

80 |

1,500,000 |

|

90BV12-30 |

2.60 |

10-500 |

0-30 |

0-1.2 |

5.5-22 |

-0.095 |

100 |

1,500,000 |

|

100BV12-40 |

3.65 |

10-500 |

0-40 |

0-1.2 |

7.5-30 |

-0.095 |

100 |

1,500,000 |

|

125BV12-50 |

4.60 |

10-500 |

0-50 |

0-1.2 |

7.5-37 |

-0.095 |

125 |

1,500,000 |

|

140BV12-70 |

6.10 |

10-500 |

0-70 |

0-1.2 |

11-45 |

-0.095 |

150 |

1,500,000 |

|

150BV12-80 |

7.63 |

10-500 |

0-80 |

0-1.2 |

11-55 |

-0.095 |

150 |

1,500,000 |

|

200BV12-120 |

11.56 |

10-400 |

0-120 |

0-1.2 |

15-75 |

-0.095 |

200 |

1,500,000 |

|

250BV12-150 |

14.22 |

10-400 |

0-150 |

0-1.2 |

18.5-90 |

-0.095 |

250 |

1,500,000 |

|

300BV12-200 |

20.80 |

10-300 |

0-200 |

0-1.2 |

22-110 |

-0.095 |

300 |

1,500,000 |

|

350BV12-300 |

32.60 |

10-250 |

0-300 |

0-1.2 |

45-160 |

-0.095 |

350 |

1,500,000 |

|

400BV12-400 |

50.40 |

10-250 |

0-400 |

0-1.2 |

55-200 |

-0.095 |

400 |

1,500,000 |

Note:

1. Tested medium: water.

2. Speed, flow rate, electrical power and pressure will be varified according to different product properties.

Selection Guidelines

|

Your Industry |

|

||

|

About pump medium |

Name: |

||

|

Density (g/m³): |

|||

|

Viscosity (mPa.s): |

|||

|

Temperature (℃): |

|||

|

PH value: |

|||

|

Solid content (%): |

|||

|

Solid size (mm): |

|||

|

Suction side |

Pressure: Positive ( ) bar; Negtive ( ) bar |

How high (m): |

|

|

Suction pipe length (m): |

Diameter (mm): |

||

|

Bends (Pcs): |

T-piece (Pcs): |

Valves (Pcs): |

|

|

Discharge side |

Pressure (Mpa): |

||

|

Vertical delivery pipe length (m): Total delivery pipe length (m): |

Diameter (mm): |

||

|

Bends (Pcs): |

T-piece (Pcs): |

Valves (Pcs): |

|

|

Required flow rate (L/H) |

Operating flow: |

Max. flow: |

|

|

Pump material required |

SS304 ( ) SS316 ( ) SS316L ( ) Duplex stainless steel ( ) |

||

|

Motor required |

Phase: Single ( ) Three ( ) |

Voltage (V): |

Frequency (Hz): |

|

IP grade: |

Energy efficiency: |

Anti-explosive: |

|

|

Installation type |

Fixed ( ) |

Movable ( ) |

Fixed with adjusting feet ( ) |

|

Others |

|

||

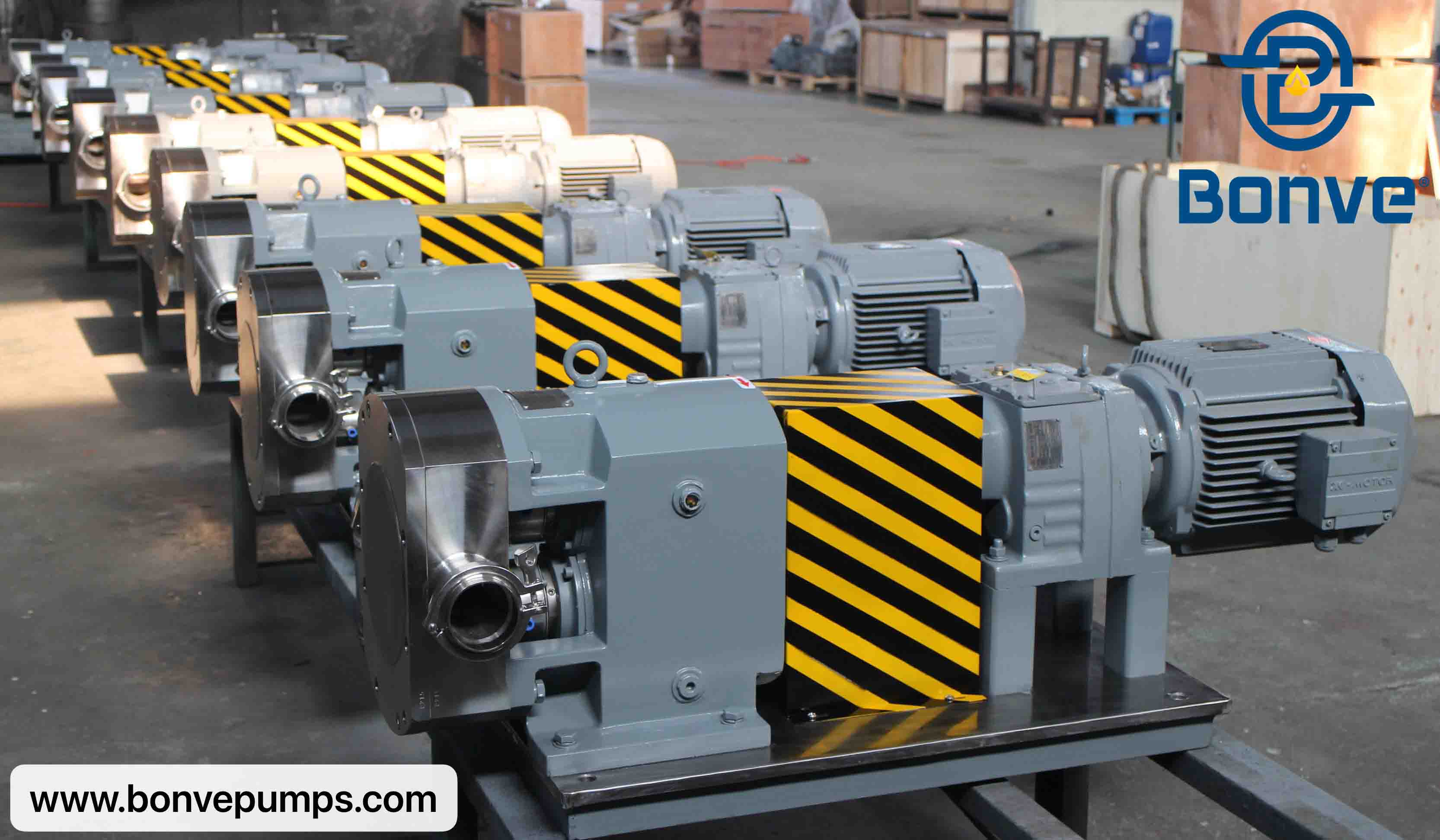

About us

BONVE is a Chinese leading manufacturer in ROTARY LOBE PUMPS and HOMOGENIZER MIXERS. Providing its customers with customized pumping and mixing solutions and solving their problems during the production.

Bonve pumps and mixers are widely used in food, dairy, beverages, chemical, pulp&paper, soaps&detergents, pharmaceuticals, pesticide, coatings etc. By 2024, Bonve served 8,000+ customers in various industries and 100,000+ pumps running in the worldwide.

Time and again companies specify Bonve pumps as the "standard" equipment for their manufacturing processed. We are looking forward to be partner with you.

Contact Us

We welcome you to contact us for a Shampoo transfer pump, Cream feeding pump, Lotion transfer pump solution if have any demand.

Contact person: Cathy Bao

Tel: +86-574-87769810 Fax: +86-574-62962898

Mobile/Whatsapp/Wechat: +86 13616639068

Email: Cathy@bonvepumps.com