PUMP INTRODUCTION

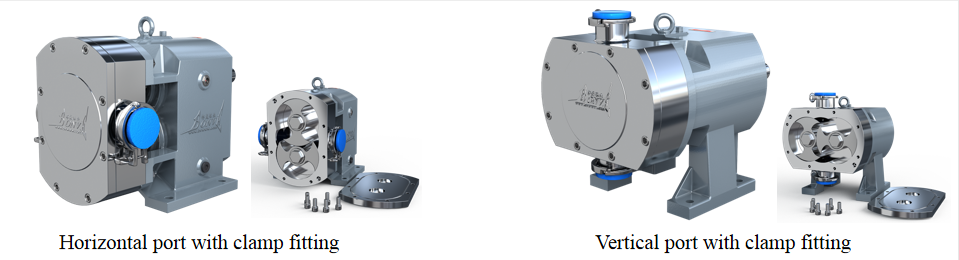

BONVE sanitary rotor pumps are the first choice for fluid transportation in food, dairy, cosmetics and other industries. The flow parts are made of stainless steel 316 or 316L, and the surface roughness is below 0.8um, which meets 3A, FDA and EHEDG standards. To meet the site installation, pump port direction can be horizontal or vertical. Vertical port pump is more sanitary because the products can be discharged fully. Port connections are workable for clamp or thread, which are easier to disassemble and assemble, and the sanitary level is high. There is a certain gap between the rotor and the rotor, the rotor and the pump cavity to avoid damage to the conveyed products. Especially suitable for high viscosity and high solid products without any physical and chemical reactions.

PUMP MAIN FEATURES

- The all main parts are made by CNC, which have high precision;

- Simple structure, easy to clean and maintaince;

- Long service life, reducing use cost;

- Energy saving, low noise;

- Various of drive method can meet customers' requirement;

- The transportable medium viscosity is upto 1.5 million cp, and the slurry with a solid content upto 70%;

- Meet CIP and SIP request;

- All contact parts are made of stainless steel 316 material;

- It can transport three-phase mixture materials such as vapor, liquid and solid.

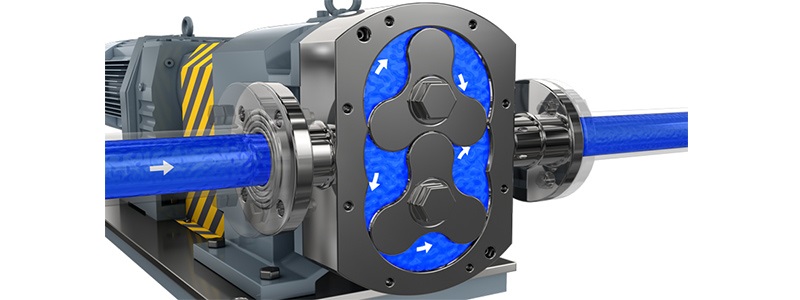

WORKING PRINCIPLE

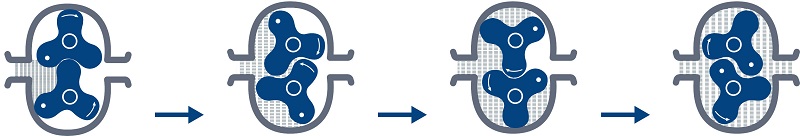

The sanitary rotor pumps adopt two lobe rotors, which rotate synchronously driven by a pair of synchronous gear in the gearbox. The rotors are driven by the main shaft and sub-shaft to rotate in a synchronous reverse direction, which changes the pump capacity, builds up high vacuum and discharge pressure, thus an efficient pumping is formed.

-

Bi-wing rotors

diagram

-

Tri-wing rotors

diagram

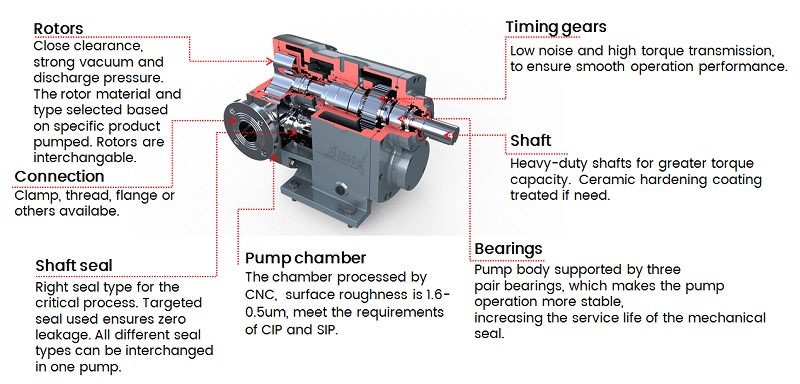

PUMP STRUCTURE

TECHNICAL PARAMETERS

| Model |

Displace -ment |

RPM | Flow | Dis. Pre. | Power | Vacuum | Port size |

Max viscosity |

|

|

(L/r) | (r/min) | (m³/h) | (Mpa) | (kW) | (Mpa) | (mm) | (cp) |

| 25BV12-05 |

0.06 |

10-1000 |

0-0.5 |

0-1.2 |

0.37-1.1 |

-0.080 | 25 | 1,500,000 |

|

40BV12-2 |

0.15 |

10-1000 |

0-2 |

0-1.2 |

0.75-2.2 |

-0.080 |

40 |

1,500,000 |

|

50BV12-5 |

0.32 |

10-800 |

0-5 |

0-1.2 |

1.5-4 |

-0.085 | 50 |

1,500,000 |

|

65BV12-10 |

0.65 |

10-600 |

0-10 |

0-1.2 |

2.2-7.5 |

-0.085 |

65 |

1,500,000 |

|

80BV12-20 |

1.74 |

10-500 |

0-20 |

0-1.2 |

4-15 |

-0.095 | 80 |

1,500,000 |

|

90BV12-30 |

2.60 |

10-500 |

0-30 |

0-1.2 |

5.5-22 |

-0.095 |

100 |

1,500,000 |

|

100BV12-40 |

3.65 |

10-500 |

0-40 |

0-1.2 |

7.5-30 |

-0.095 |

100 |

1,500,000 |

|

125BV12-50 |

4.60 |

10-500 |

0-50 |

0-1.2 |

7.5-37 |

-0.095 |

125 |

1,500,000 |

|

140BV12-70 |

6.10 |

10-500 |

0-70 |

0-1.2 |

11-45 |

-0.095 |

150 |

1,500,000 |

|

150BV12-80 |

7.63 |

10-500 |

0-80 |

0-1.2 |

11-55 |

-0.095 |

150 |

1,500,000 |

|

200BV12-120 |

11.56 |

10-400 |

0-120 |

0-1.2 |

15-75 |

-0.095 |

200 |

1,500,000 |

|

250BV12-150 |

14.22 |

10-400 |

0-150 |

0-1.2 |

18.5-90 |

-0.095 |

250 |

1,500,000 |

|

300BV12-200 |

20.80 |

10-300 |

0-200 |

0-1.2 |

22-110 |

-0.095 |

300 |

1,500,000 |

|

350BV12-300 |

32.60 |

10-250 |

0-300 |

0-1.2 |

45-160 |

-0.095 |

350 |

1,500,000 |

|

400BV12-400 |

50.40 | 10-250 | 0-400 |

0-1.2 |

55-200 |

-0.095 |

400 |

1,500,000 |

APPLICATIONS

- Beverages: Beer,carbonated soft drinks, coffee liquor, fruit juice concentrates, milk drinks, sugar solutions, wine, yeast slurries.

- Confectioneries: Biscuit cream, caramel, chocolate, cocoa butter, cocoa mass, condensed milk, fat, fondant, glucose, high-boiled sugar syrup, jellies.

- Dairies: Butter, cheese, cream, egg, ice cream, milk, quarg, whey, yoghurt.

- Pharmaceutica: Blood, cell cultures, enzymes, ointments, protein solutions, syrups.

- Prepared Foods: Additives, baby food, edible oils, fruit puree, meat chunks, jam, petfood, sauces, soups, toppings.

- Consumer products: Soap & Detergents, AES, LAS, AOS, K12, glycerin, fatty alcohol, bath shampoo, skin cream, shampoo, detergent, toothpaste, liquid soap, washing power slurry, etc.

- Sugar: Glucose, high or low green syrup, liquid sugar, magma, massecuite, molasses, sugar syrup, thick juice, treacle.

OUR STRENGTHS

Expert in manufacturing of rotary lobe pumps, it is worth to get your truth.

High precision processing machines to make pumps, to make sure the supplied pumps are top-performance.

Abundant parts in stock guarantees the delivery time.

Strict inspection to guarantee the supplied are high quality.

Certificate by authority organization:

ISO9001:2015 approved

CE certified

OUR PARTNERS

CONTACT US

We welcome you to contact us for a pump solution if have any demand.

Contact person: Mr. Tom

Tel: +86-574-87769810 Fax: +86-574-62962898

Mobile/Whatsapp/Wechat: +86 13375846933

Email: trade@bonvepumps.com