THREE-STAGE INLINE HIGH SHEAR HOMOGENIZER MIXERS

Bonve Three-stage (FHM3) inline high shear homogenizer mixers is an efficient type machine with mixing, dispersion, breaking, dissolution, refinery, homogenization and emulsifying. It is an ideal machine to be instead of colloid mill, ball mill and high pressure homogenizer. The machine can greatly simplify the traditional productions and upgrade the production efficiency and product quality.

Features:

100% dispersive shear;

Quickly dissolves solids without agglomeration;

No dead ends, high evenness;

Time-saving, high-efficiency, low-consumption;

Simple operation, convenient maintenance, and can realize automatic control.

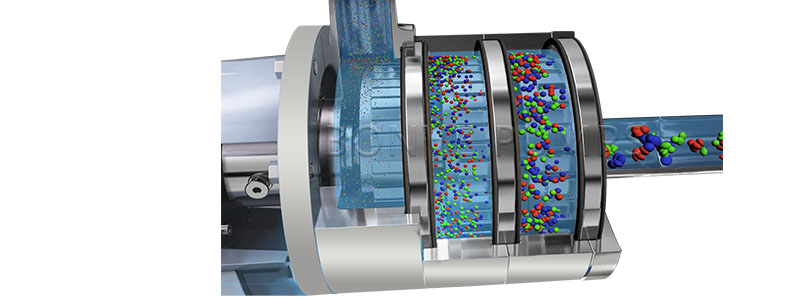

WORKING PRINCIPLE

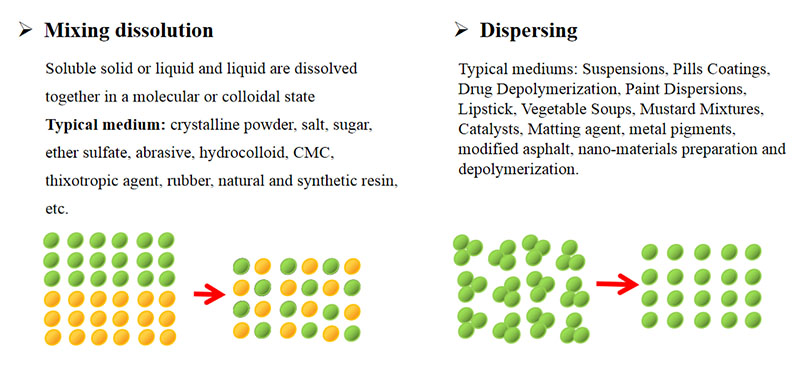

The main parts are stators and rotors. At centrifugal and fluid forces created by rapid turning of the rotors, the stators exercise on the materials with strong power shearing, centrifugal pressing, breaking, fluid friction, turbulent. The processed materials (solid, fluid and gas phase) are quickly refined, homogenized, dis-aggregated and emulsified. The repeat of this process can result in stable and high-quality products.

PRODUCT LINE: FHM1 AND FHM3 SERIES

Bonve inline high shear homogenizer mixers are mainly devided into 2 series based on different numbers of rotor and stator, working types. (The pump with 2-stage rotor and stage can be made too)

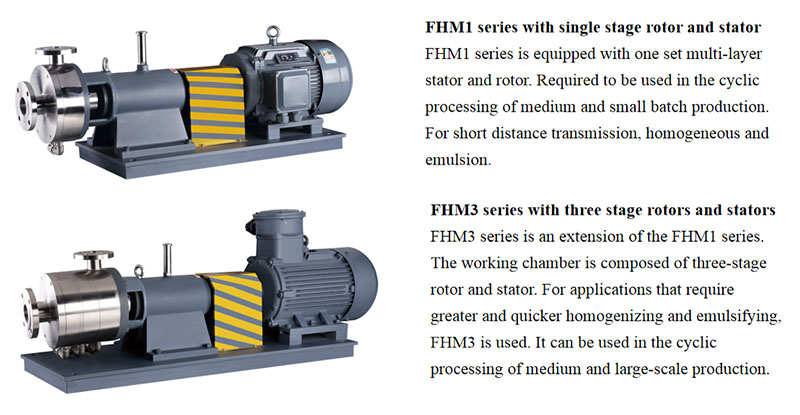

FHM1 series with single stage rotor and stator

FHM1 series is equipped with one set multi-layer stator and rotor. Required to be used in the cyclic processing of medium and small batch production.For short distance transmission, homogeneous and emulsion.

FHM3 series with three stage rotors and stators

FHM3 series is an extension of the FHM1 series.The working chamber is composed of three-stage rotor and stator. For applications that require greater and quicker homogenizing and emulsifying.FHM3 is used. It can be used in the cyclic processing of medium and large-scale production.

MAIN TECHNICAL PARAMETERS: FHM1

| Model |

Electrical Power (kW) |

Rotation Speed (r/min) |

Capacity (m3/h) |

Discharge pressure (Mpa) |

Diameter of inlet/outlet (mm) |

| FHM1/165 | 7.5/11 | 2900 | 0-10 | 0.15 | DN50/40 |

|

FHM1/185 |

11/15 |

2900 |

0-15 | 0.15 | DN65/50 |

|

FHM1/200 |

15/18.5 |

2900 |

0-20 | 0.15 | DN80/65 |

|

FHM1/220 |

22/30 |

2900 |

0-30 | 0.15 | DN80/65 |

|

FHM1/240 |

30/37 |

2900 |

0-50 | 0.15 | DN100/80 |

|

FHM1/260 |

37/45 |

2900 |

0-60 | 0.15 | DN125/100 |

|

FHM1/300 |

45/75 |

2900 |

0-80 | 0.15 | DN125/100 |

MAIN TECHNICAL PARAMETERS: FHM3

| Model |

Electrical Power (kW) |

Rotation Speed (r/min) |

Capacity (m3/h) |

Discharge pressure (Mpa) |

Diameter of inlet/outlet (mm) |

| FHM3/165 | 18.5 | 2900 | 0-10 | 0.30 | DN50/40 |

|

FHM3/185 |

30 |

2900 |

0-20 | 0.30 | DN65/50 |

|

FHM3/200 |

45 |

2900 |

0-30 | 0.30 | DN80/65 |

|

FHM3/220 |

55 |

2900 |

0-40 | 0.30 | DN80/65 |

|

FHM3/240 |

90 |

2900 |

0-60 | 0.30 | DN100/80 |

|

FHM3/260 |

132 |

2900 |

0-100 | 0.30 | DN125/100 |

|

FHM3/300 |

160 |

1400 |

0-120 | 0.30 | DN150/125 |

Remarks:

1. Abovedates are tested by water. For product with poor liquidity or require a higher discharge pressure, Bonve lobe pump is advised to be installed before the homogenizer for transferring.

2. Port size can be changed as needed. Flange connection as starndard, clamp and thread as optional.

3. Motor matched is Siemens, ABB or equivalent brand. Normal type with 3ph/380V/50Hz as standard.

4. MOC: SS316 as standard, SS304, 316L and others as optional. 150°C (302°F) anti-heat seal.

5. Bonve reserves the right to change specifications without prior notification.

APPLICATIONS

Refined chemistry: Pigment, dyestuff, plastic auxiliaries, textile auxiliaries, adhesives, resin emulsion, hot melt adhesive, sealing compound, glue, pulp, finishing agent, surface active agent, carbon black disperse, adhesive-proof agent, mold release agent, defoaming agent, fluorine cleaning agent, polishing agent, leather auxiliaries, pigment paste, wax emulsion, bactericide, coagulant, etc.

Petrochemistry: Lubricant, heavy oil emulsion, diesel oil emulsion, modified asphalt, catalyzer, wax emulsion etc.

Biology & Pharmaceuticals: Injection, antibiotic, medical emulsion, medical paste, health products, mini-capsule emulsion, cell breaker, etc.

Paint & ink: Printing ink, paint, emulsion paint, building coating, nanometer coating, photocureable coating, coating auxiliaries, carbon black disperse, print ink, glaze, bentonite, etc.

Farm chemicals: Pesticide, herbicide, medicinal butter, fertilizer, pesticide adjuvant, etc.

Nanometer materials: Disperse and dis-aggregation for nanometer medium, etc.

Food stuff industry: Juice, jam, ice-cream, milk products, food addictive, tea drink, chocolate, bean milk, essence, milk, etc.

Consumer chemistry: Fluid detergent, skim cream, lip paste, face foam, silicon lio emulsion, household essence, skin care, cosmetics, etc.

Paper making: Pulp, filling, fry strength agent, wet strength agent, sizing agent, filtering agent, anti-foaming agent spreading, water treatment chemicals, etc.

WORKING PROCESS

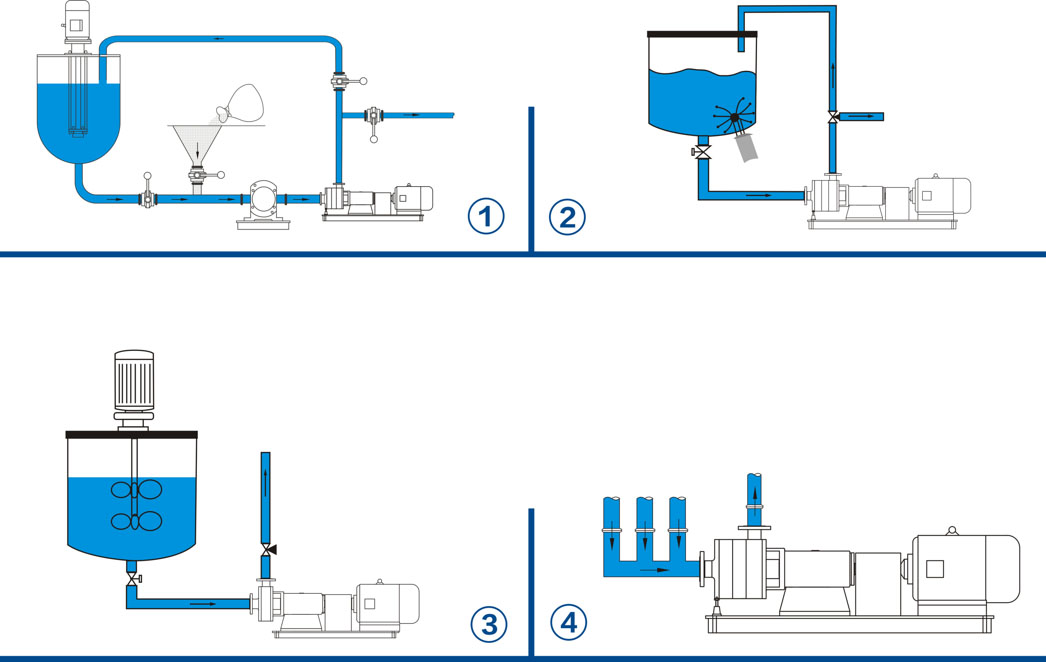

For various processes, different equipment is used to match and optimize the combination, so that the system achieves the best working effect. The common process flow diagram is as follows:

① High shear mixer working with powder liquid homogenizing mixer. For high viscous products, Bonve lobe pump is necessary to work together

② Bottom type high shear mixer working with FHM3 homogenizing mixer

③ Low speed agitator working with FHM1 homogenizing mixer

④ Multi-pipe FHC homogenizing mixer continuous production process

SELECTION GUIDELINE

|

Your industry/application |

|

|

Processed medium’s name |

|

|

Medium’s feature |

Sanitary ( ) Corrosive ( ) Poisonous ( ) |

|

Medium’s proportion |

Liquid % ____ Density____ Viscosity____ PH value____ Solid % ____ Solid size ___ |

|

Processing requirement |

Mixing dissolving ( ) Dispersed suspension ( ) Emulsification ( ) Homogeneity ( ) Reaction ( ) Powder liquid mixing ( ) |

|

Working type |

Continuous circulation work ( ) Batch type ( ) |

|

Working temperature |

|

|

Particle size |

Before processing ____ After processing _____ |

|

Handling capacity required |

|

|

Delivery head/pressure required |

|

|

Vessel's dimension |

|

|

Existing pipe size and connection type |

|

|

The existing process equipment and the existing problems |

|

For a quick quotation, please email cathy@bonvepumps.com to ask about selection guideline. Your inuqiry will be welcome and get our prompt reply. Thanks for your interest and love for Bonve Three-stage inline high shear homogenizer mixers.