The Rotor Pump achieves the purpose of transporting fluid by means of periodic conversion of a plurality of fixed volume delivery units in the working chamber. The Rotor Pump passes through a pair of synchronously rotating rotors during operation. The rotor is driven by a pair of synchronizing gears in the pump body, and rotates in the opposite direction through the main shaft and the auxiliary shaft. The volume of the pump is varied to produce vacuum and discharge pressure. Rotor Pump is particularly suitable for the transport of sanitary media, corrosive and high viscosity media. Different medium has different characteristics. Pump rotor type should be selected accordingly. And it has the following types:

Single-wing rotor: This type of rotor is rarely used. It has large pulsation, low pressure and low volume, but it has low shearing to particles. Usually, it is selected to transfer liquid with big size particles, like melon seeds, peanuts, corns, puddings, food residue etc.

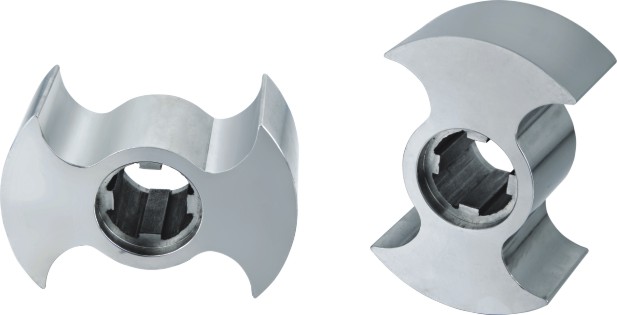

Double-wing rotor: This is a general-purpose rotor. It has long service life because wear loss we made is almost zero. It is selected to convey liquid which has middle and small size particles because low shearing to the particles when pumping. What’s more, this type rotor is also a good choice to pump liquid with high density and viscosity with its stable working. No change to liquid composition.

Tri-lobe rotor: This type rotor has a certain breaking to granular medium. It is suitable for conveying clean mediums. Its volume is bigger than other types of rotors, which is more suitable to transfer liquid with poor liquidity.

Multi-impeller rotors: The stability of the multi-impeller rotor is relatively improved, and it plays a mixed role in the conveying process. When the impeller numbers exceeds three pieces, more impellers less volume, more impellers higher accuracy of the metering. Pump equipped with this type rotor and frequency inverter, It can be used as a metering pump. Frequency inverter can fulfill flow adjusted at will.

Which rotor is best for you? It depends on your application. Plus there are several other things to be considered for selection like flow, pressure, liquid temperature, PH value. If you aren't sure, contact us and we can help you walk through it and offer you most satisfied pump.